Computer numerical control (CNC) machining is a specialized manufacturing process that uses computer technology to guide equipment. This makes it possible to automate production processes and increase the volume of production in industrial facilities. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

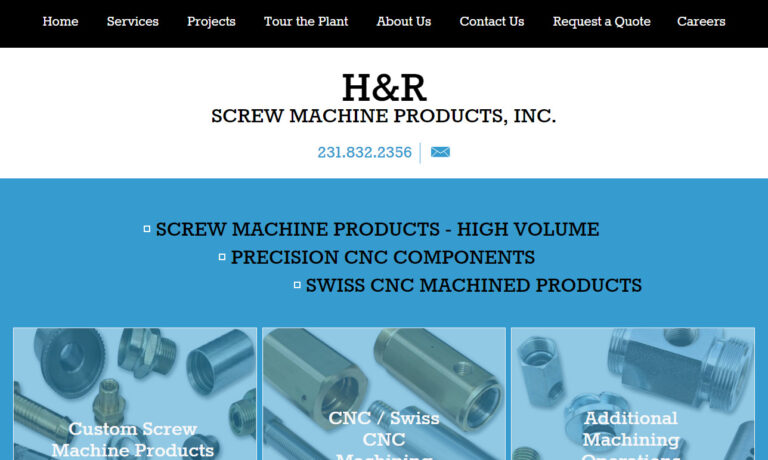

H & R is a custom manufacturer of high volume superior parts, providing CNC machining for tight tolerance and also lower volume applications too.

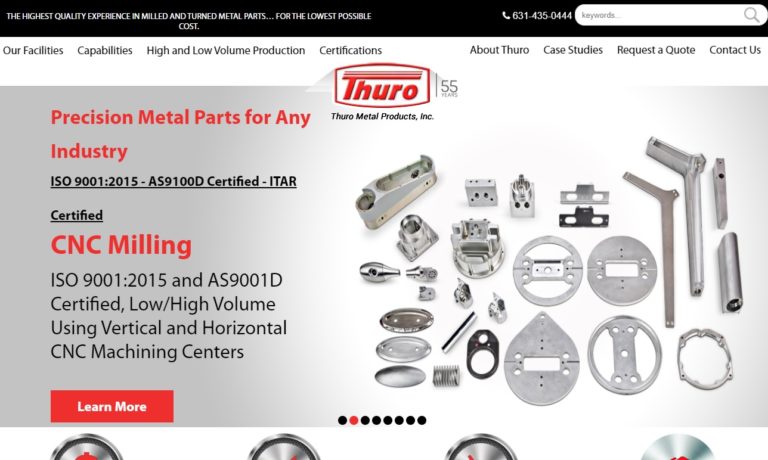

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More CNC Machining Companies

CNC Machining Benefits

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computer-controlled machines to produce precise and complex parts from various materials. It uses specialized software customized and programmed with G-code, a language allowing precise control of parameters such as speed, location, coordination, and feed rate. This advanced technology offers numerous benefits compared to traditional manual machining methods. Here are some of the key advantages of CNC machining:

Precision and Accuracy: CNC machining excels in precision and accuracy by delivering consistent and repeatable results through computer-controlled automation. These machines can achieve tight tolerances within fractions of a millimeter, minimizing human error and ensuring precise dimensions and geometries. Advanced positioning systems, multi-axis capabilities, and digital control with feedback mechanisms contribute to the high precision of CNC machining. Quality assurance measures, such as in-process inspections and post-machining measurements, further validate the accuracy of the parts. The precision and accuracy of CNC machining make it indispensable in industries where reliability, functionality, and intricate designs are paramount, such as aerospace, automotive, electronics, and medical sectors.

Increased Efficiency: CNC machining offers increased efficiency through automation, faster production cycles, and optimized resource utilization. The automation and continuous operation of CNC machines reduce the need for constant manual intervention, enabling uninterrupted production and maximizing machine utilization. Quick changeover capabilities and flexibility allow for efficient transitions between different part designs, minimizing downtime. CNC machines optimize cutting parameters, perform simultaneous operations, and reduce errors and rework, resulting in streamlined production processes and improved overall efficiency. These efficiency gains lead to faster time-to-market, higher productivity, and cost savings in modern manufacturing operations.

Repetitive Operations: CNC machining excels in repetitive operations by delivering consistent quality and dimensions, enabling high-speed production, accommodating long production runs, and ensuring consistent quality control. The automated nature of CNC machines ensures that each part is produced with the same programmed instructions, resulting in consistent and replicated outcomes. CNC machines can operate at high speeds while maintaining accuracy, allowing for faster production cycles and increased productivity. They are well-suited for long production runs of identical parts, as they can continuously produce without frequent manual adjustments. CNC machining incorporates quality control measures, such as in-process inspections and post-machining measurements, to verify the quality and accuracy of the parts, ensuring consistent quality throughout repetitive operations.

Versatility: CNC machining offers exceptional versatility in manufacturing, providing several key benefits. Its ability to work with a wide range of materials, including metals, plastics, composites, and wood, allows for material selection based on specific application requirements. This versatility extends to diverse industries such as automotive, aerospace, electronics, and furniture, accommodating industry-specific needs. CNC machining is scalable for both small and large production runs, enabling efficient production of prototypes, customized parts, and high-volume manufacturing. Additionally, its compatibility with secondary operations and post-processing techniques enhances versatility by integrating surface treatments, heat treatment, engraving, polishing, and assembly. The versatility of CNC machining makes it a highly adaptable and valuable technology across various industries and applications.

Complex Geometries: CNC machining excels in working with complex geometries, thanks to its multi-axis capabilities, 3D cutting, precision, adaptive tooling, and integration with CAD/CAM software. By utilizing multiple axes and 3D cutting, CNC machines can produce intricate shapes and contours that are challenging to achieve with manual machining. The precision and accuracy of CNC machining ensure consistent replication of complex geometries, while adaptive tooling and machining strategies address challenges posed by intricate features. The seamless integration with CAD/CAM software enables designers to create intricate 3D models and translates them into machine-readable instructions. Overall, CNC machining’s ability to handle complex geometries opens up possibilities for intricate designs and precise dimensions in industries such as aerospace, automotive, and medical.

Flexibility and Customization: CNC machining offers remarkable flexibility and customization capabilities, providing several key benefits. Its ability to adapt to different designs and specifications allows for quick changes and customization. By simply updating the program, CNC machines can produce different parts, prototypes, or modifications as needed, making it highly versatile in meeting specific requirements. CNC machining is particularly valuable in rapid prototyping and small-batch production, as it allows for rapid design iterations and customization without the need for extensive retooling. This flexibility enables manufacturers to respond quickly to design changes, market demands, and customer preferences, ensuring a faster time-to-market and the ability to cater to individual needs.

Improved Safety: CNC machining offers improved safety in several ways, ensuring a safer working environment for operators. Compared to manual machining, CNC machines minimize physical contact between operators and cutting tools or workpieces, reducing the risk of accidents and injuries. Operators have limited interaction with the machining process, as CNC machines operate autonomously based on programmed instructions. This decreases the chances of operator fatigue, inattentiveness, or human error that can lead to accidents. CNC machines are equipped with safety features such as emergency stop buttons, protective enclosures, and safety interlocks that prevent access to the working area during operation. Additionally, advanced tool monitoring systems can detect tool wear or failures, reducing the likelihood of tool-related accidents. The integration of safety protocols and technologies in CNC machining promotes a safer working environment, protecting the well-being of operators and minimizing potential risks.

Lower Error Rate: CNC machining significantly reduces the error rate compared to manual machining, resulting in improved overall product quality. Once the program is accurately set up, CNC machines execute the instructions precisely, minimizing the chances of errors caused by operator fatigue, inattentiveness, or inconsistency. The automation and precise control of the machining process in CNC machines ensure consistent and repeatable results, reducing variations and deviations from the desired specifications. Additionally, CNC machines often incorporate built-in checks and feedback systems, allowing for real-time monitoring and adjustment during the machining process. This helps detect and rectify any deviations or errors promptly, further minimizing the error rate. By reducing human-induced errors and improving consistency, CNC machining ensures a higher level of quality and reduces the need for costly rework or scrap, ultimately increasing productivity and customer satisfaction.

Time and Cost Savings: CNC machining offers significant time and cost savings throughout the manufacturing process. Once the program is set and the machine is running, CNC machining operates autonomously, reducing the need for constant manual intervention and supervision. This improves production efficiency and throughput, resulting in shorter lead times and faster time-to-market. Additionally, CNC machines optimize cutting parameters, minimizing material waste and reducing the need for post-machining adjustments or rework. The precise control and automation of CNC machining reduce the chances of errors and subsequent time-consuming corrections. These factors, coupled with the ability to handle complex designs and versatile production capabilities, contribute to overall cost savings. CNC machining reduces labor costs by minimizing manual labor requirements, while the elimination of human errors and rework reduces material waste and associated costs. The time and cost savings offered by CNC machining make it a cost-effective solution for modern manufacturing operations.

Overall, CNC machining offers precise, efficient, and versatile manufacturing capabilities that result in improved productivity, quality, and cost-effectiveness. Its ability to handle complex designs and materials makes it an essential technology in modern manufacturing industries.

CNC Applications

CNC machining has countless applications. With it, manufacturers make parts and products for virtually all industries. Some of the industries that most heavily rely on CNC production machining include industrial manufacturing, metalworking, aerospace, architecture, electronics energy, oil and gas, marine, military and defense, and medicine and healthcare.

Products Produced by CNC Machining

Metalworking

Examples of some of the products that manufacturers make to assist in metalworking include dies, coinage dies, molds, fittings, equipment components (gears, shafts, shaft assemblies, etc.), and the like.

Woodworking

CNC machining is utilized in woodworking to cut, carve, and shape wooden components, allowing for the creation of intricate designs, custom furniture pieces, cabinetry, decorative moldings, and other wood products with high precision and repeatability.

Automotive

CNC machining is used in the automotive industry to produce various components such as engine parts, transmission components, chassis components, interior and exterior trim pieces, and other critical parts requiring high precision and reliability.

Electronics

CNC machining is employed in the electronics industry for the production of circuit boards, connectors, heatsinks, enclosures, and other parts that require precise machining and intricate designs in order to meet the specific requirements of electronic devices and components.

Aerospace

Examples of products that manufacturers CNC for the aerospace industry include ground support equipment, compressor cases, control panels, separation discs, electronic enclosures, electronic housings, and instrument panels.

Energy

Examples of products that manufacturers CNC machine for the energy industry include light assemblies, solar energy cells, housings, gear cases, covers, hubs, brackets, couplings, guides, sleeves, weldments, fluid manifold blocks, gas blocks, motion components, and shaft components.

Furniture

CNC machining is utilized in the production of furniture to cut, shape, and carve wooden components with precision and efficiency, allowing for the creation of intricate designs, custom furniture pieces, cabinetry, decorative moldings, and other wood products. CNC machines offer the ability to achieve complex shapes, intricate detailing, and repetitive operations, making them valuable tools in the furniture manufacturing industry.

Oil and Gas

Manufacturers use CNC machining to create countless products for oil and gas. Examples include spacers, connected rod bushings, pump liners, wrist pin bushings, drill bit parts, hydraulic components, electric submersible pumps, valving systems, actuating systems, sealing systems, vacuum systems, and blowout preventers.

Marine

Some of the many marine industry products that manufacturers CNC machines include connecting shafts, arrester gears, valves, flanges, engine parts, propulsion systems, transmission units, power trains, and marine power units.

Military and Defense

Examples of CNC machined military and defense parts and products include clamshells, fuser rollers, flanges, retainer rings, track hubs, main rotor hubs, missile components, aircraft seat frames, helicopter components, aerospace couplers, naval structural systems, naval shift components, naval engines, transmission components, and munitions hoist components.

Medicine and Healthcare

For medicine and healthcare, manufacturers CNC machine products like spinal fusion cages, expandable rib cages, bone plates, maxillofacial prosthetics, endovascular devices, vena cava clips, surgical forceps, surgical equipment, blood delivery housings, dental scalers, and fixation devices.

Miscellaneous

Miscellaneous products that manufacturers make using CNC machining include household fixtures, satellite system components, ball joints, valve bodies, internal computer assemblies, semiconductor components, suspension arms, thermal device components, spindle housings, tensioners, fasteners, input shafts, output shafts, rail and switch gears, module blocks, and more.

History of CNC Machining

Engineers built the very first computer numerical control machines during the 1940s and 1950s. Their inventions were essentially motorized tools that followed points as they were directed by inputs from punched tape. Later, engineers added analog computers and digital computers into the mix.

In the 1970’s, manufacturers began making practical uses of the very basic versions of CNC machining software available to them. The technology available to them was initially limited.

Since then, huge changes and developments in computer technology have made the process much more precise and reliable. Improved codes have made CNC machines easier for beginners to operate. With computer imaging software, manufacturers are able to involve their clients in the product design before production begins. They may even use the machines to create one or several prototypes before going into full scale production. After a production run is over, the product code can be filed away for use in the future.

Today, CNC manufacturers do more than manufacture a final product. They consult, design, and optimize production for their clients.

CNC Machining Service Details

CNC machining services are professional manufacturing services that utilize computer-controlled machines to produce precise and customized parts based on client specifications. These services typically involve the following details:

Material Selection: CNC machining services offer a wide range of material options, including metals (such as aluminum, steel, brass, titanium), plastics (such as ABS, PVC, nylon), composites, wood, and more. The choice of material depends on the specific application, desired properties, and functional requirements of the part.

Design and Programming: Clients provide their design specifications, which can be in the form of 2D drawings, 3D models, or CAD files. The CNC machining service provider assists in optimizing the design for manufacturability and advises on material selection, tolerances, and machining strategies. Once the design is finalized, it is converted into machine-readable instructions using computer-aided manufacturing (CAM) software.

CNC Machining Process: The CNC machining service provider sets up the CNC machine by installing the necessary tools, fixtures, and workholding devices. The program generated in the previous step is loaded into the CNC machine’s computer system. The machine then performs the machining operations, such as milling, turning, drilling, and cutting, based on the programmed instructions. CNC machines can perform multi-axis operations to achieve complex geometries and intricate details.

Quality Assurance: CNC machining services often have quality control measures in place to ensure the produced parts meet the required specifications. This can involve in-process inspections, post-machining measurements, and the use of advanced metrology equipment, such as coordinate measuring machines (CMMs). Inspection reports and certificates of conformance may be provided to verify the quality and accuracy of the parts.

Finishing and Post-Processing: Depending on the client’s requirements, CNC machined parts may undergo additional finishing processes. These can include surface treatments like anodizing, plating, painting, or powder coating to enhance appearance, corrosion resistance, or other functional properties. Deburring, polishing, and assembly services may also be offered.

Packaging and Shipping: Once the parts have undergone quality checks and any required finishing processes, they are carefully packaged to ensure protection during transportation. The CNC machining service provider may offer various shipping options to meet the client’s needs, including express delivery or international shipping.

Collaboration and Communication: Throughout the CNC machining service process, effective communication and collaboration between the client and the service provider are crucial. Clear communication of design requirements, material specifications, and delivery deadlines helps ensure the successful completion of the project. Regular updates, progress reports, and prompt responses to inquiries contribute to a smooth and efficient service experience.

CNC machining services provide clients with access to advanced manufacturing capabilities, expertise in material selection and design optimization, and the convenience of outsourcing production to specialized providers. By leveraging CNC machining services, businesses can benefit from efficient and accurate production processes, high-quality parts, and faster turnaround times.

CNC Machining Design

When designing your part or product in their CNC machine shop, manufacturers consider a number of factors. These include the material capabilities you require, your requested product volume, your required product diameter, etc. Based on these factors, manufacturers will decide what processes are necessary to design and create your part, what software they should use, and the best material(s) for your part.

Some of the many materials that CNC machining manufacturers may pick from include wood, plastics, ceramic, metals (carbon steel, mild steel, stainless steel, aluminum, brass, copper, titanium, etc.), super alloys, and glass.

It’s easy for CNC machining service providers to create custom products for you. To learn more, talk over your application with your potential suppliers.

CNC Machinery Used

Vertical milling machines work using cutting tools that move on a vertical axis. Note, though, that vertical milling machines can cut or drill from the front, side or from above, as long as the tools move there vertically. Typically, manufacturers use vertical axis mills to form 1D shapes.

Horizontal milling machines hold and move cutting tools on a horizontal axis. They work like vertical milling machines, except that they also use a rotary table that lets them make contact at multiple angles. Because of what they allow, rotary tables used in this setting are often called “universal tables.” Horizontal mills are more expensive than vertical mills, but they are more versatile and work extremely well.

CNC cutting machines make cuts with extreme precision. Where and how deep they cut depends on the carefully coded instructions given to them by the CNC technology. CNC machines can direct cutters to operate on up to six different axes of motion at once.

CNC drilling machines typically feature of number of different turrets or spindles. To quickly alter what they are drilling, the tool bits housed inside turrets or spindles are automatically rotated or changed out by CNC tool changers. Automated changes are as quick as two seconds.

CNC lathes, which are similar to CNC turning (milling) machines, machine workpieces by shaping them as they rotate. They can wield a number of different machine tools at once, such as drills and cutters. Older CNC lathe models use two axes, but newer lathes use more, allowing manufacturers to take on more complex projects. CNC lathes usually read G-code.

CNC Machining Variations and Similar Services

CNC milling (CNC turning) is the most common type of CNC manufacturing on the market, but companies who specialize in precision CNC machining often offer more detailed CNC machining services.

Some of the most common of these precision CNC machining services include cutting, drilling, and grinding. These functions can be CNC programmed into a single unit, or the unit can have several machine tool heads that are engaged during particular tasks.

CNC turning is a precise CNC machining method in which the workpiece is rotated adjacent to a rotating single-point cutting tool. Lathes, such as turret lathes, engine lathes, and engine-purpose lathes, are the most often used tools for turning operations.

CNC milling, sometimes called CNC turning, is a CNC precision machining process that manufacturers most often use to engrave materials. Milling is a precision machining procedure that includes removing extra material from a product with rotary cutters. There are many mills involved. End mills, chamfer mills, and helical mills are examples of such mills. People call it CNC turning because the machine rotates as it works. CNC milling machines work well for engraving because they engage turning machine tools, like cutters and conical tools, on multiple axes at once. Manufacturers can perform CNC turning quickly without sacrificing quality.

CNC cutting involves the use of all kinds of tooling and processes (e.g. lasers, blades, plasma cutting, waterjet cutting, etc.), with the help of CNC technology, to remove material from a workpiece. The goal of CNC cutting is to shape or finish a 2D or 3D part or product with tight tolerances.

CNC drilling involves the use of machines to bore holes or threads of different shapes and sizes, as guided by computer software. Drilling is a precision machining method that creates cylindrical holes in raw materials/workpieces by using spinning multi-point drill bits. Manufacturers can modify CNC drilling machines to drill into all kinds of materials. CNC drilling is efficient and effective. Examples of some of the industries in which manufacturers use CNC drilling include military and defense, recreation, automotive manufacturing, aerospace, agriculture, pharmaceutical processing, chemical processing, and food and beverage.

CNC grinding is a CNC machining process during which CNC software controls an abrasive belt, disc, or wheel. The abrasive element finishes parts and products by removing unnecessary surface material.

CNC plasma cutters use a powerful laser to cut. Most plasma cutters cut programmed shapes out of sheets or plates.

Precision CNC machining, which uses coded programming instructions, allows a workpiece to be cut and shaped to specifications without the need for manual intervention from a machine operator. Precision CNC machining is frequently the fabrication method of choice for many of the tiny parts and components utilized in a wide variety of produced products.

Beyond drilling, grinding, milling, and cutting, secondary services like finishing, anodizing, heat treating, lapping, stress relieving, and polishing may all be accomplished by special CNC equipment.

Things to Consider Regarding CNC Machining

Some manufacturers only have a limited number of machines, while others stock a wide variety so that they can accommodate a broader range of projects. Every machining center is different. To find a manufacturer with both the right skills and right capabilities for you, make sure to thoroughly discuss your application requirements with your potential suppliers. We recommend that, before you talk to any candidates, you put together a list of these application requirements, so that you don’t forget anything when you talk to them. Remember to include things like your request volume, your standard requirements, your budget, your timeline, your delivery preferences, and your post-delivery support preferences.

Once you have put this list together, check out our list of suggested suppliers. You will find it by scrolling towards the middle of this page. All of those we have listed are high quality CNC machining suppliers. Determine which manufacturer might be right for you by first by comparing their respective capabilities and offered services to your list of specifications. Pick three or four CNC machining companies that you believe hold potential for you. Then, reach out to each of them to discuss your application, using your specifications list as a conversation guide. Finally, compare and contrast each of your conversations. Determine which service provider is right for you, then get started with them.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services