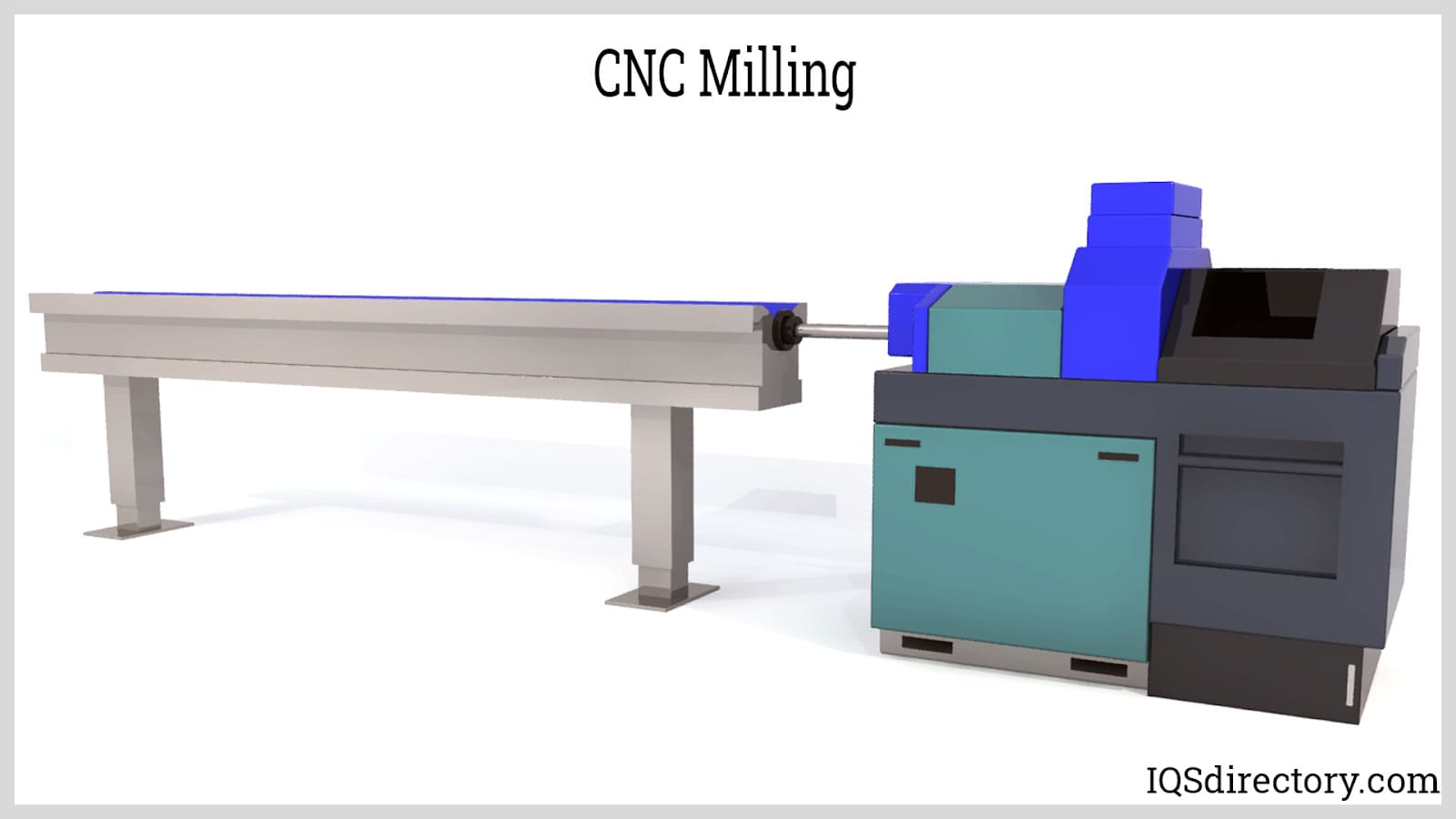

CNC milling is a type of machining process utilizing a CNC (computer numerical control) machine whereby cutting tools and computerized controls are utilized for the selective removal of material from a workpiece so that a custom-designed part is produced. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

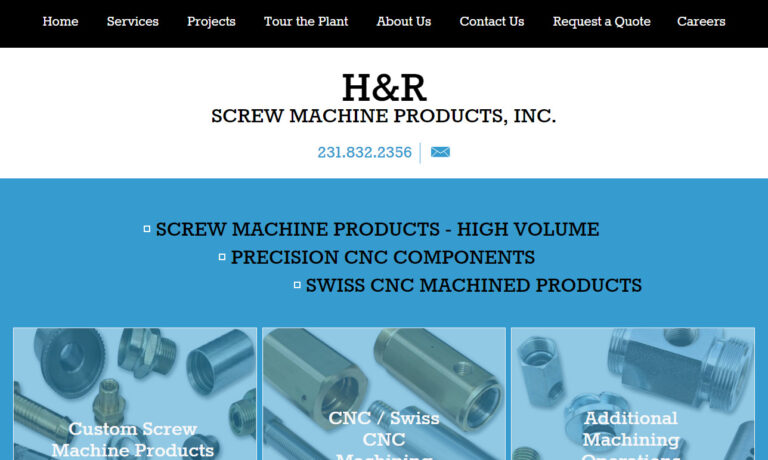

H & R is a custom manufacturer of high volume superior parts, providing CNC machining for tight tolerance and also lower volume applications too.

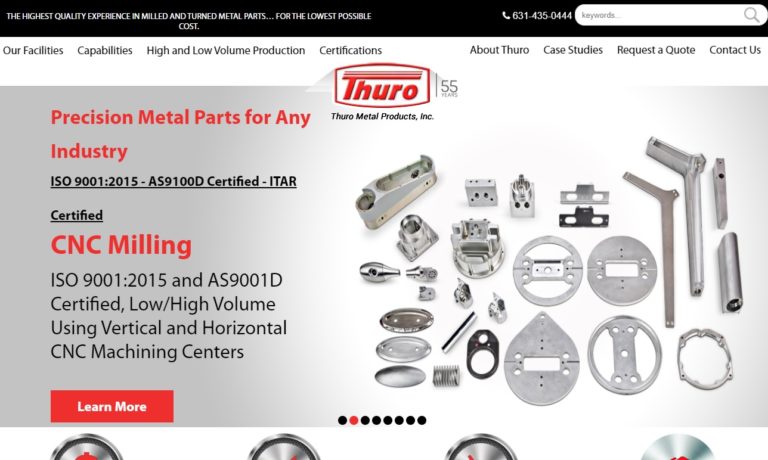

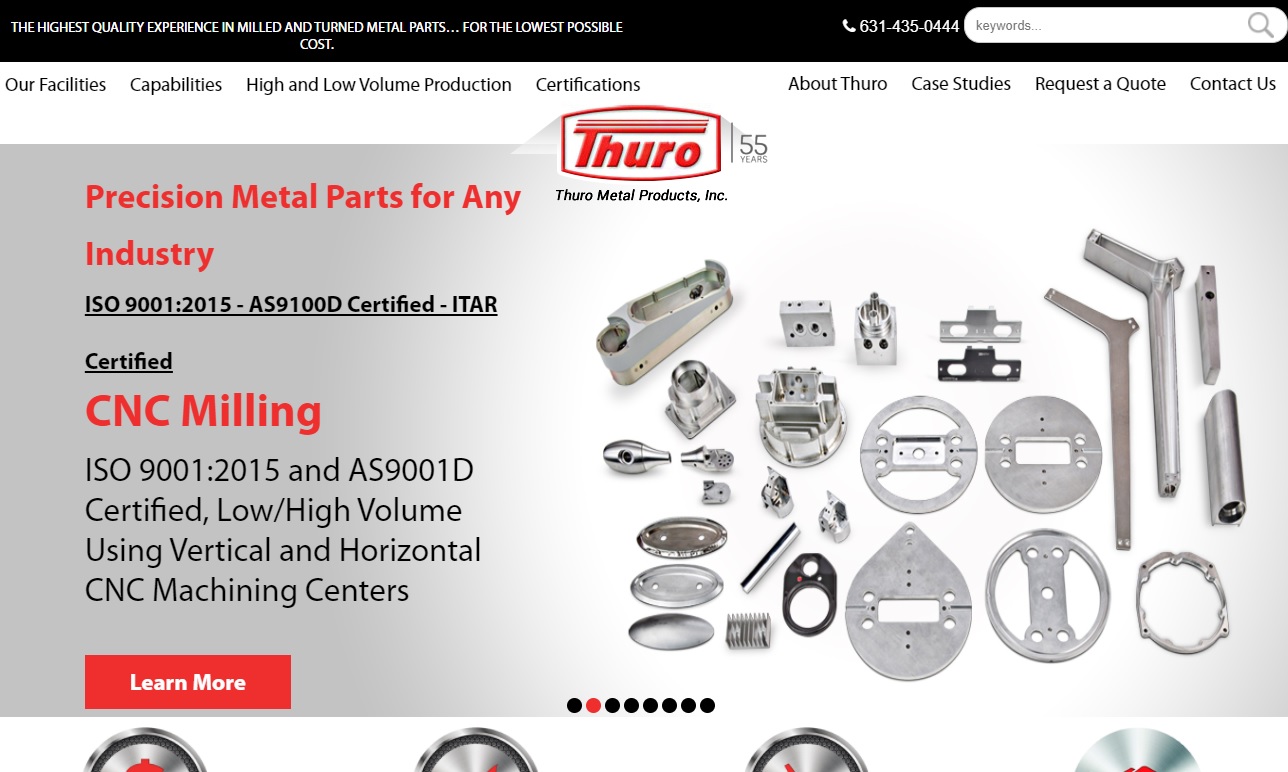

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More CNC Milling Manufacturers

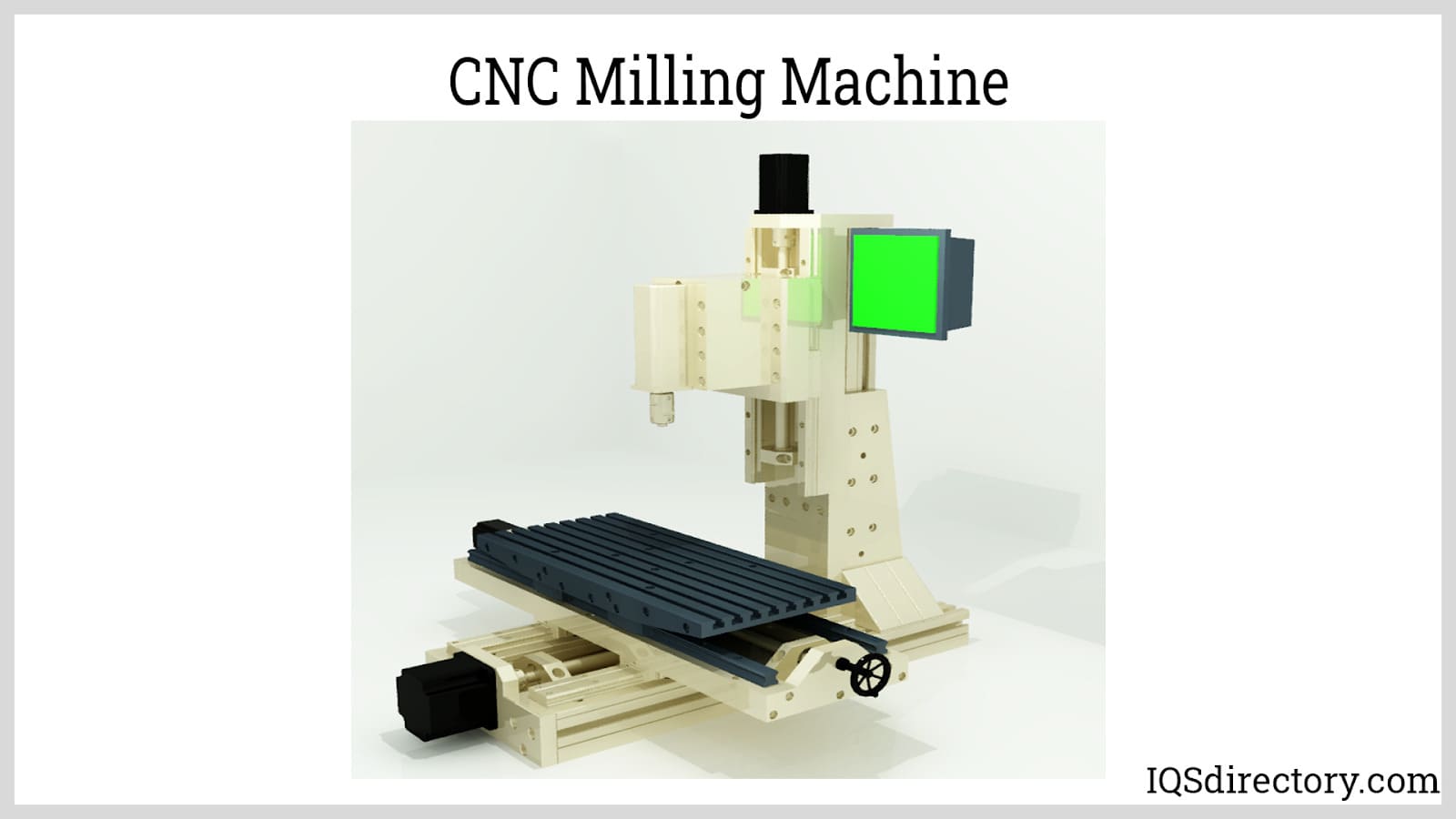

What is CNC Milling?

This machine consists of a table that automatically rotates the workpiece on various planes so that the cutting tool can work on it. The working principle of CNC machining is based on the conversion of a 3D, CAD (computer-aided design) model into a set of computer instructions. These computer instructions are then used for automatically dictating the actions of the tooling as well as movements of a CNC mill.

Types of CNC Milling

CNC milling comes in these different varieties:

Vertical Milling

With vertical milling, the tooling rotation of this type of milling process runs vertically- that is in the direction of gravity. This process utilizes a simple vertical CNC milling machine with three axes where the movement of the tooling is vertical.

The movement of the table is from the front to the back of the machine, and also from side to side. The machines used in vertical milling are very common in most machine shops since they are simple to program and cost-effective, but still offer diverse capabilities.

Horizontal Milling

This type of milling process utilizes horizontal milling machines with a similar primary function as vertical machines. In the horizontal milling machines, the spinning of the tooling is horizontal. Horizontal milling machines are usually more expensive than vertical milling machines but they are more suitable for production machining. Horizontal milling machines often have a fourth axis of rotation.

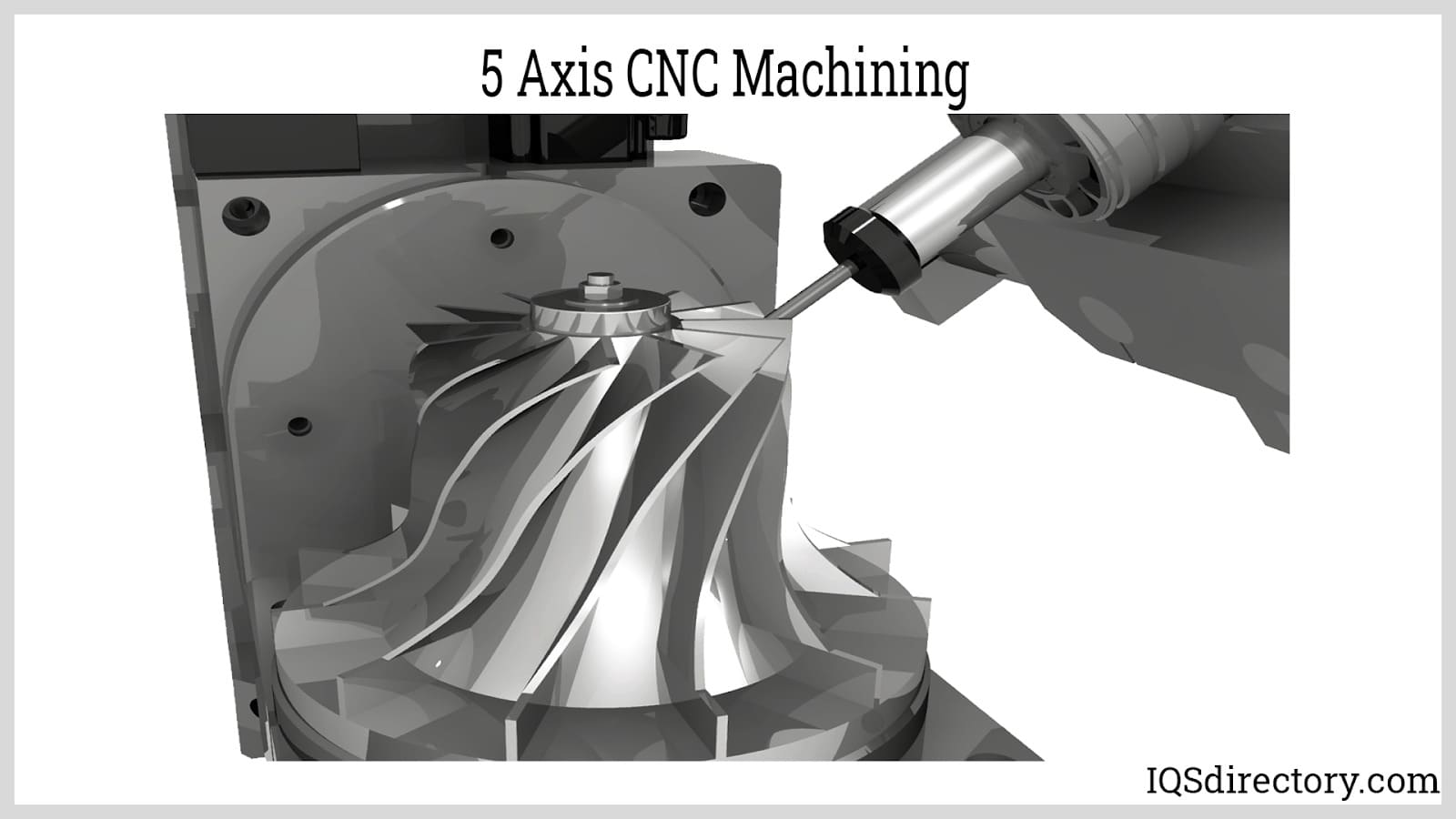

Multi Axis CNC Milling

This type of CNC milling utilizes machines with an additional axis that provides additional types of movements. These types of machines expand the capability of CNC milling machines since they are beyond the three-axis machines.

Applications of CNC Milling

- CNC milling is used in the aerospace industry for the production of bushings, manifolds, and landing gear parts.

- CNC milling is used in the medical industry for the creation of medical instruments, prostheses, as well as other medical devices.

- The electronics industry also utilizes the process of CNC milling. CNC milling is used for the creation of amplifier housings as well as heat sinks.

- CNC milling is used in the automotive industry for prototyping and production purposes. CNC machining is used for the machining of extruded material into gearboxes, cylinder boxes, blocks, axles, valves, and other various components.

Benefits of CNC Milling

Fast and Efficient

Conventional milling machines need an operator to manually change the cutting tools depending on the operation that is to be performed. This is time-consuming and also inefficient since the results are based on the operator’s judgment.

On the other hand, CNC milling machines feature rotating carousels that are capable of holding up to 30 different tools. These tools are exchanged automatically on the spindle during machining operations. This, in turn, allows for the quick and efficient performance of different cutting operations.

Affordability

CNC milling is one of the most affordable manufacturing processes available today. The components that are produced by the CNC milling process cost less than comparable 3D-printed parts and parts created through many other procedures.

Broad Range of Material Options

With CNC milling, a wide range of materials can be machined. These materials include metals, plastics, various composites, etc.

Precision

CNC milling machines are capable of creating parts that are exactly to specification. Since CNC milling machines depend on computer instructions for the fabrication of parts, they eliminate human error, which is a common possibility in manually-operated milling machines. This means that complex parts can be accurately created while achieving tolerances that are as tight as 0.004mm.

Drawbacks of CNC Milling

More Wastage of Material

CNC milling is a subtractive type of manufacturing method. This production process begins with a block of material. As the process progresses, the portions of the part are cut away to form the finished part. This results in more material wastage than in additive manufacturing processes like 3D printing.

Lack of Skilled Technicians

Even though the whole CNC milling process is automated, it still requires highly-trained engineers and technicians that are able to program the mills, calculate the requirements, and supervise the mills for the production of high-quality parts.

Choosing the Proper CNC Milling Company

For the most constructive outcome when selecting a CNC milling company, it is important to compare several companies using our directory of CNC milling businesses. Each CNC milling company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each CNC milling business website using our proprietary website previewer for a better understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple CNC milling businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services