GrovTec Machining

GrovTec MachiningRequest A Quote

Wood Village, OR | 503-557-4689https://www.grovtecmachining.com/

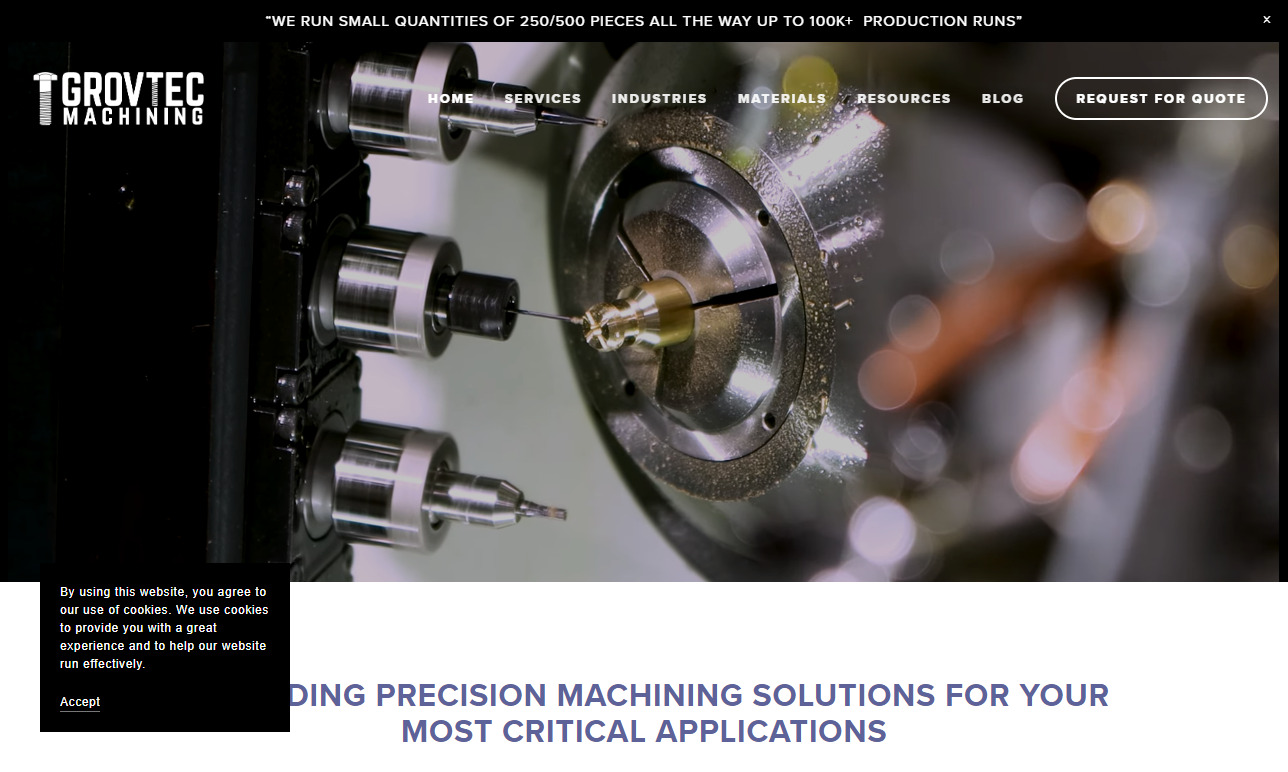

At GrovTec Machining, we pride ourselves on being the go-to destination for CNC machining capabilities and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities. Our capabilities extend far beyond conventional machining. With a commitment to excellence, we specialize in delivering high-quality products that meet and exceed our clients' expectations. Whether you require custom-made components or large-scale production runs, we have the expertise to handle it all with precision and efficiency. Time is of the essence in today's fast-paced business world, and we understand that. That's why we take great pride in providing quick turnaround times, ensuring that you receive your parts precisely when you need them. From concept to delivery, we streamline the entire process to guarantee your satisfaction. At GrovTec Machining, our dedication to outstanding customer service sets us apart. We value the relationships we build with our clients and prioritize clear communication throughout the entire manufacturing process. We work closely with you to understand your specific needs and ensure that the end product meets your exact requirements. When you choose GrovTec Machining, you're partnering with a company that is fully committed to providing top-notch products and service. Experience the difference our screw machine products and CNC machining capabilities can make for your business. Get in touch with us today, and let's bring your machining projects to life with unmatched quality and efficiency.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services