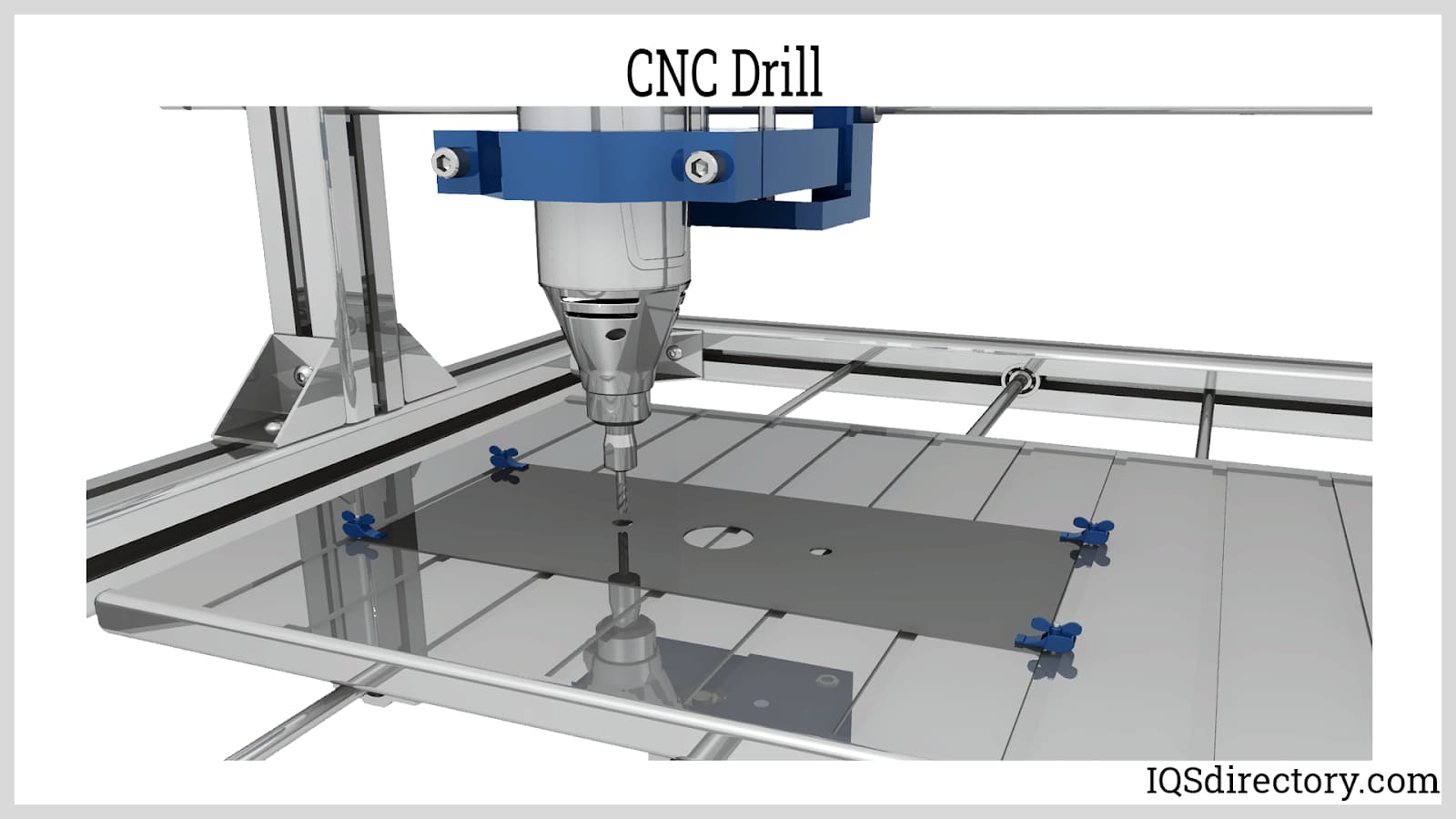

CNC (computerized numerical control) drilling is an automated process that involves rotating cutting tools to produce round holes on a stationary workpiece. This drilling is carried out to accommodate the screws and bolts needed later to hold objects together and finish the production process of various items. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

H & R is a custom manufacturer of high volume superior parts, providing CNC machining for tight tolerance and also lower volume applications too.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More CNC Drilling Manufacturers

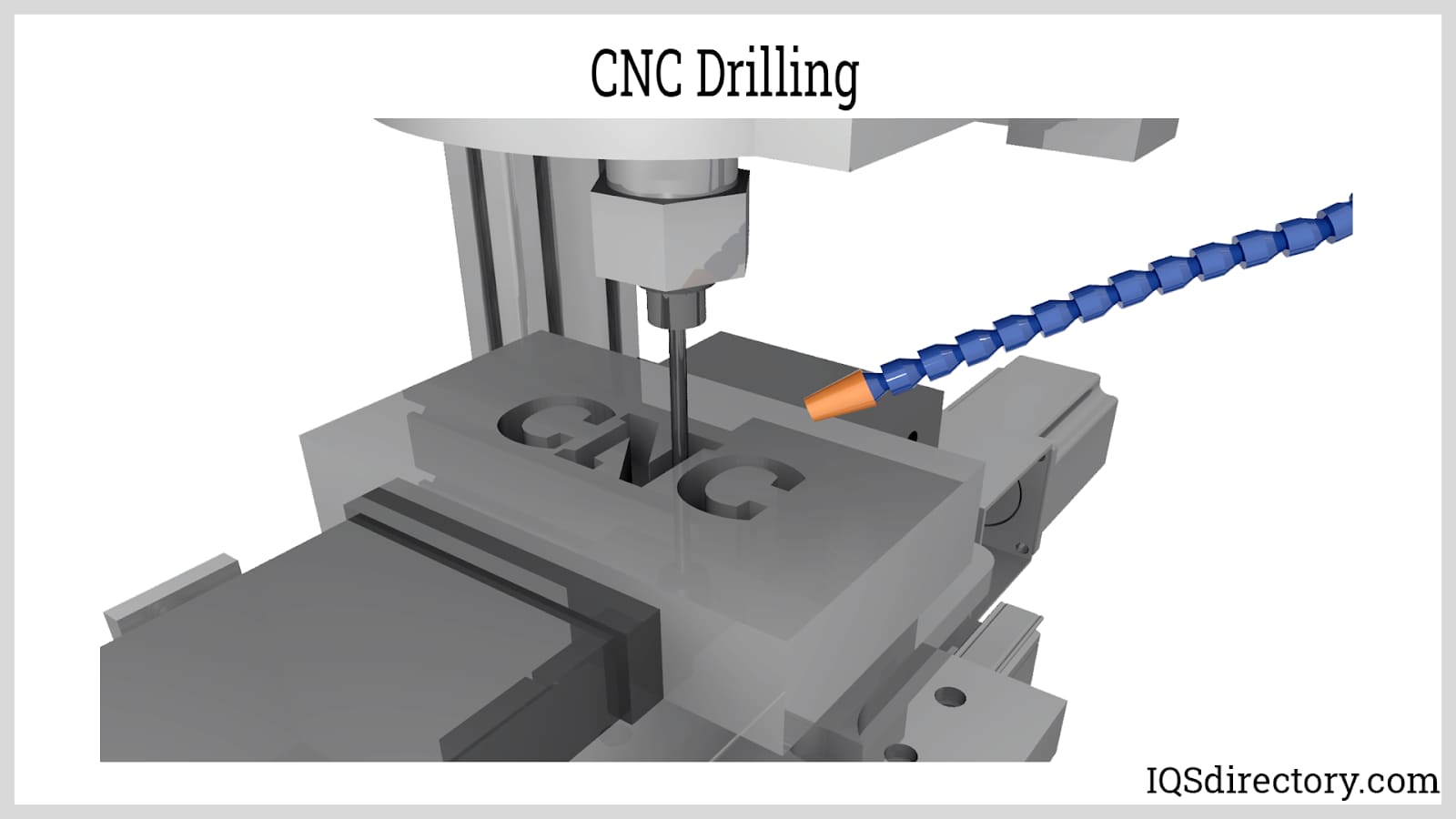

How Does CNC Drilling Work?

The CNC drilling process uses a spindle that secures the drill bits, chucks, and other moving parts in the mechanism. A computer control panel is used to activate and operate the machine. A CAD (computer-aided design) or CAM (computer-aided manufacturing) file type contains the drill settings like the speed, rate of feed, spindle positions, required diameters, and drilling depth.

After the manufacturing process, these parts are inspected for compliance, and any required changes are made as needed. Equipment maintenance and repairs are advised after every use. Furthermore, users should inspect drill bits for cracks and changes.

Types of CNC Drilling Machines

The types of CNC drilling machines include:

Upright drill press

The upright drill press is a CNC drill featuring a geared spindle drive head, and it is mainly designed for heavy, large parts. Unlike most other drills, It is commonly known for feeding a workpiece to the cutting tool and not vice versa.

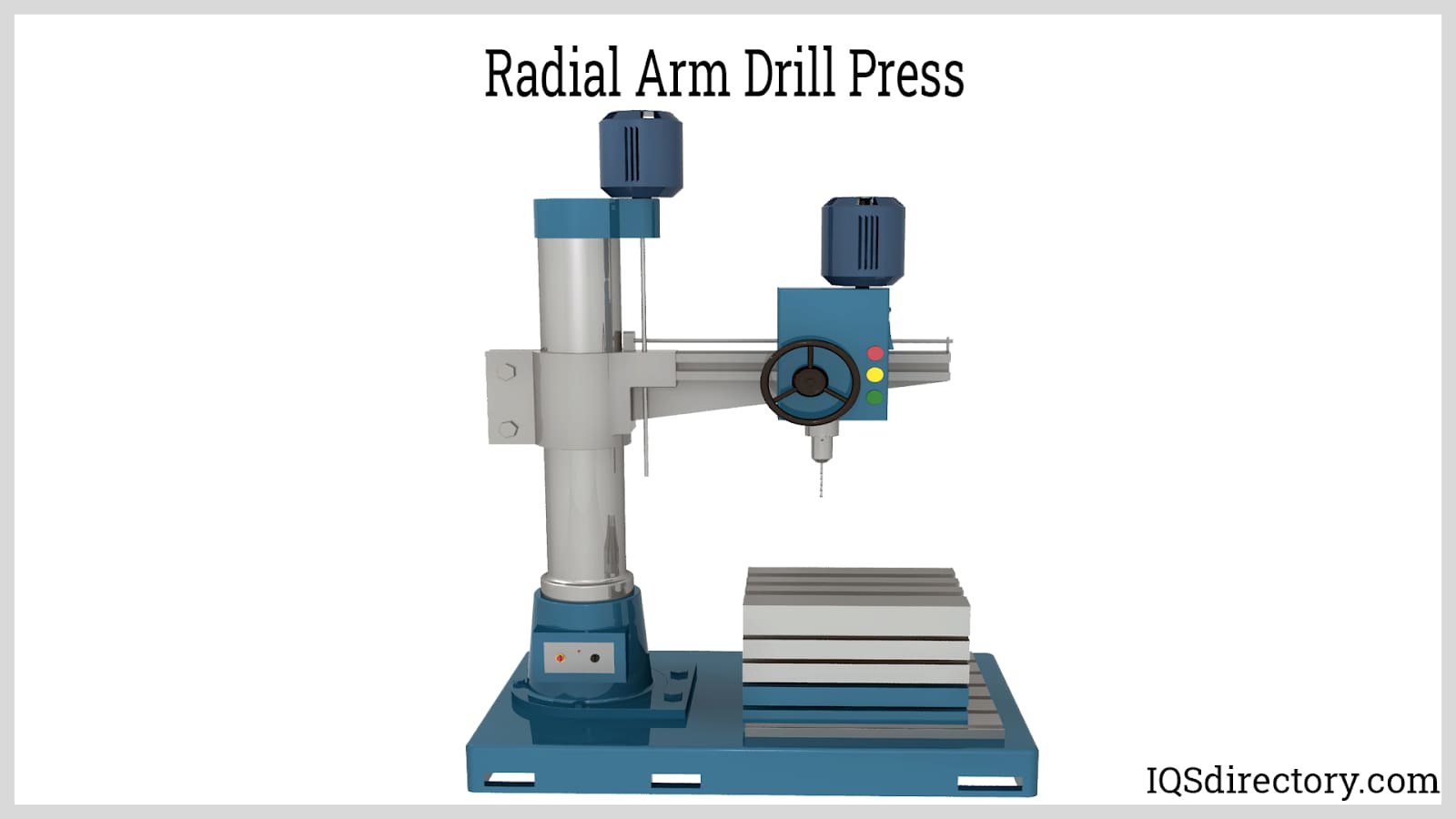

Radial arm drill press

This CNC drilling machine adopts the basic mechanism of setting a moving spindle on a stationary workpiece. The wheel head provides a cutting tool that can perform multiple operations on the parts presented in different sizes and forms.

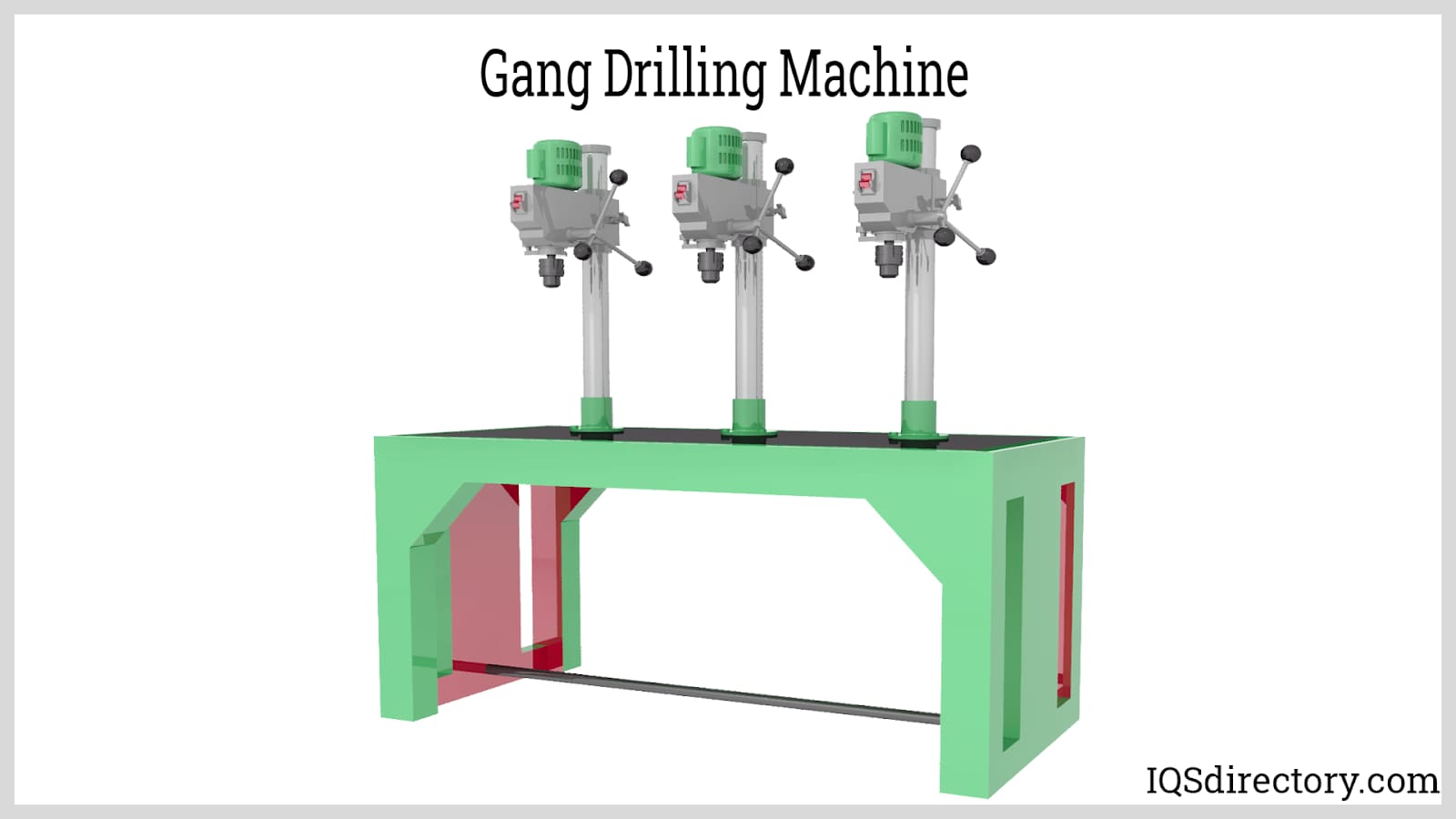

Gang drilling machine

A gang drilling machine has numerous work heads. The work heads are positioned on a work table where the part is mounted or fixed. It facilitates the simultaneous processing of what would otherwise require numerous successive operations.

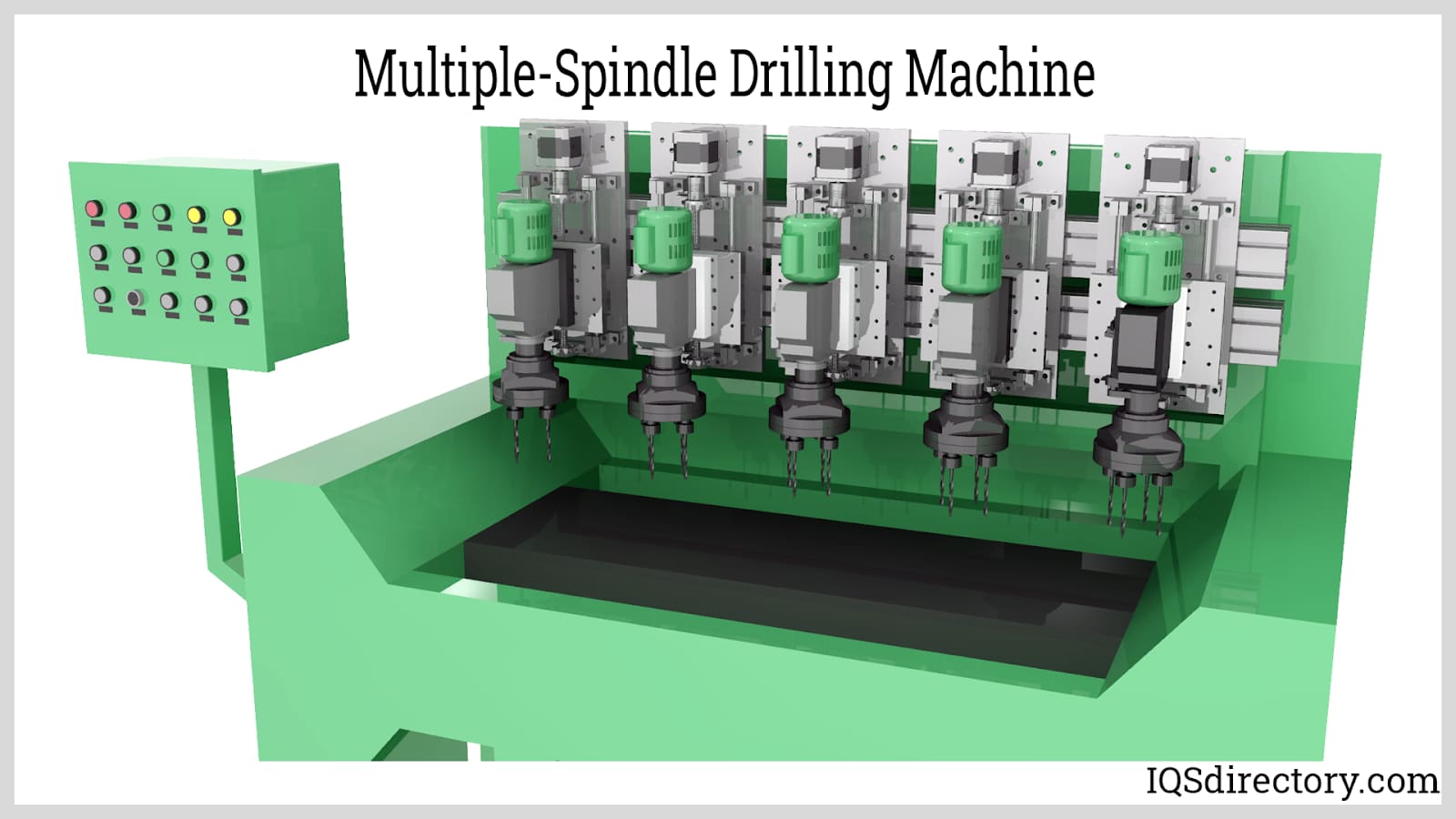

Multiple-spindle drilling machine

As the name indicates, the multiple-spindle drilling machine has multiple spindles connected to a single work head. These spindles are all fed to the workpiece simultaneously. These machines are utilized in the production of components requiring many closely-packed holes.

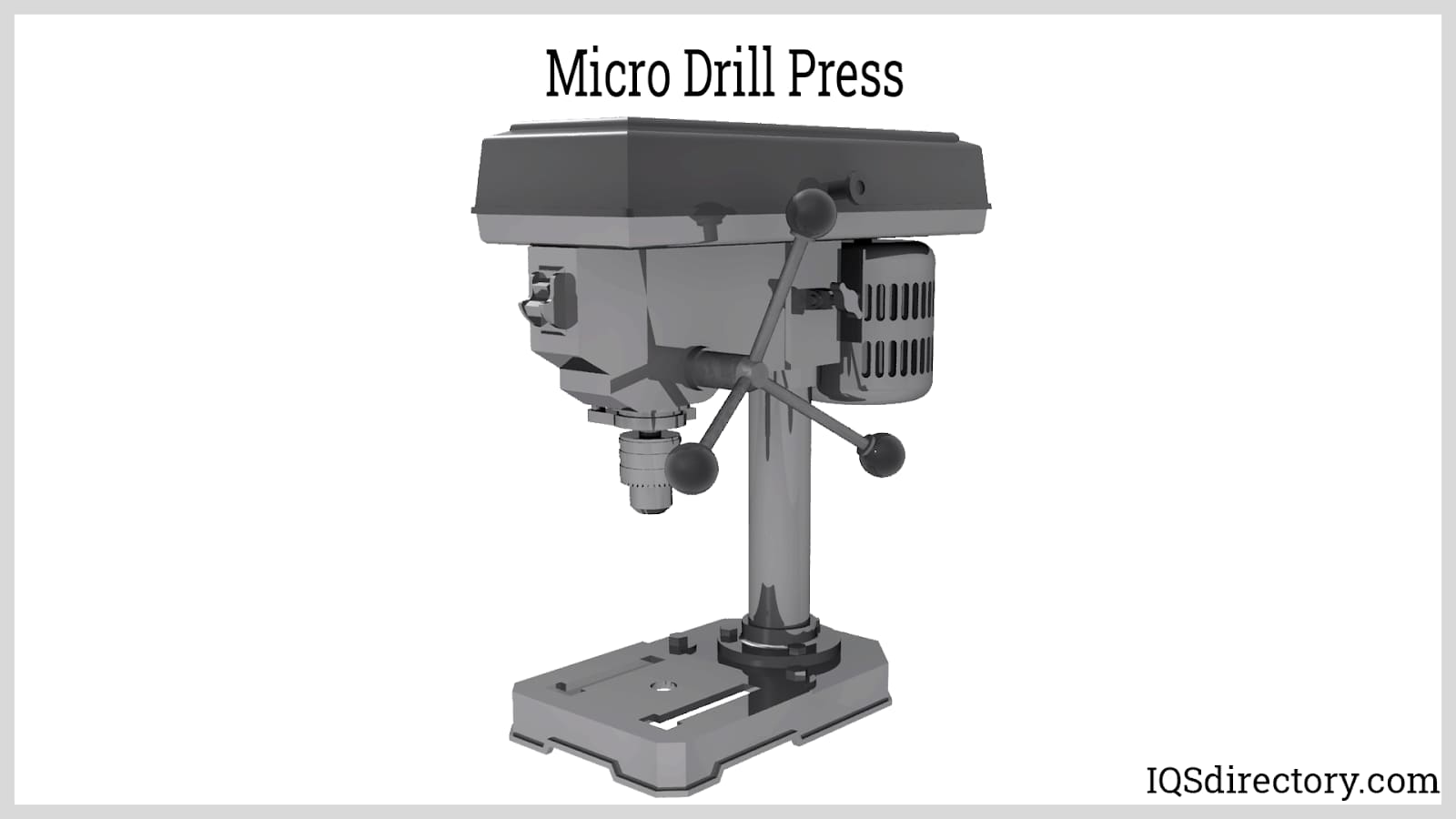

Micro drill press

A micro drill press is a small and very accurate drilling machine. It has very small chucks and is typically used when dealing with small parts and shaping them.

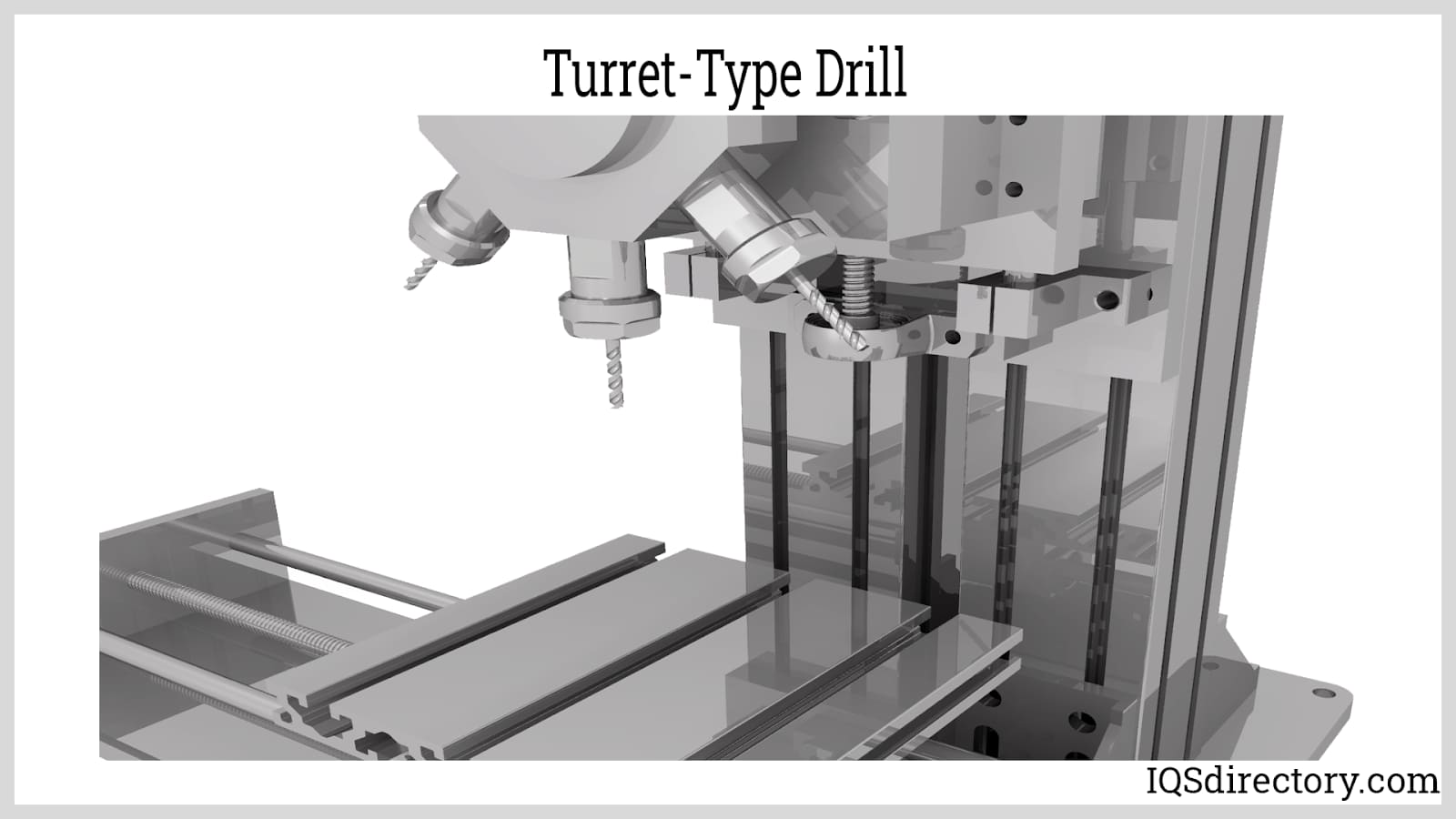

Turret-type drill

The turret-type drill has numerous work heads that are mounted on a turret. This configuration allows for quickly changing the required cutting or drilling tools and positioning over the workpieces.

Applications of CNC Drilling

Metal fabrication

CNC drilling is mainly used in metal fabrication processes such as those required for the automobile or aerospace industries. Metal piercings, perforations, and designs are all more- easily made by CNC drills.

Additionally, many metal (and other) products require precise drilling that only CNC drills may deliver within a specific timeframe. Such products include wheel hubs, gear blanks, and custom-designed shafts.

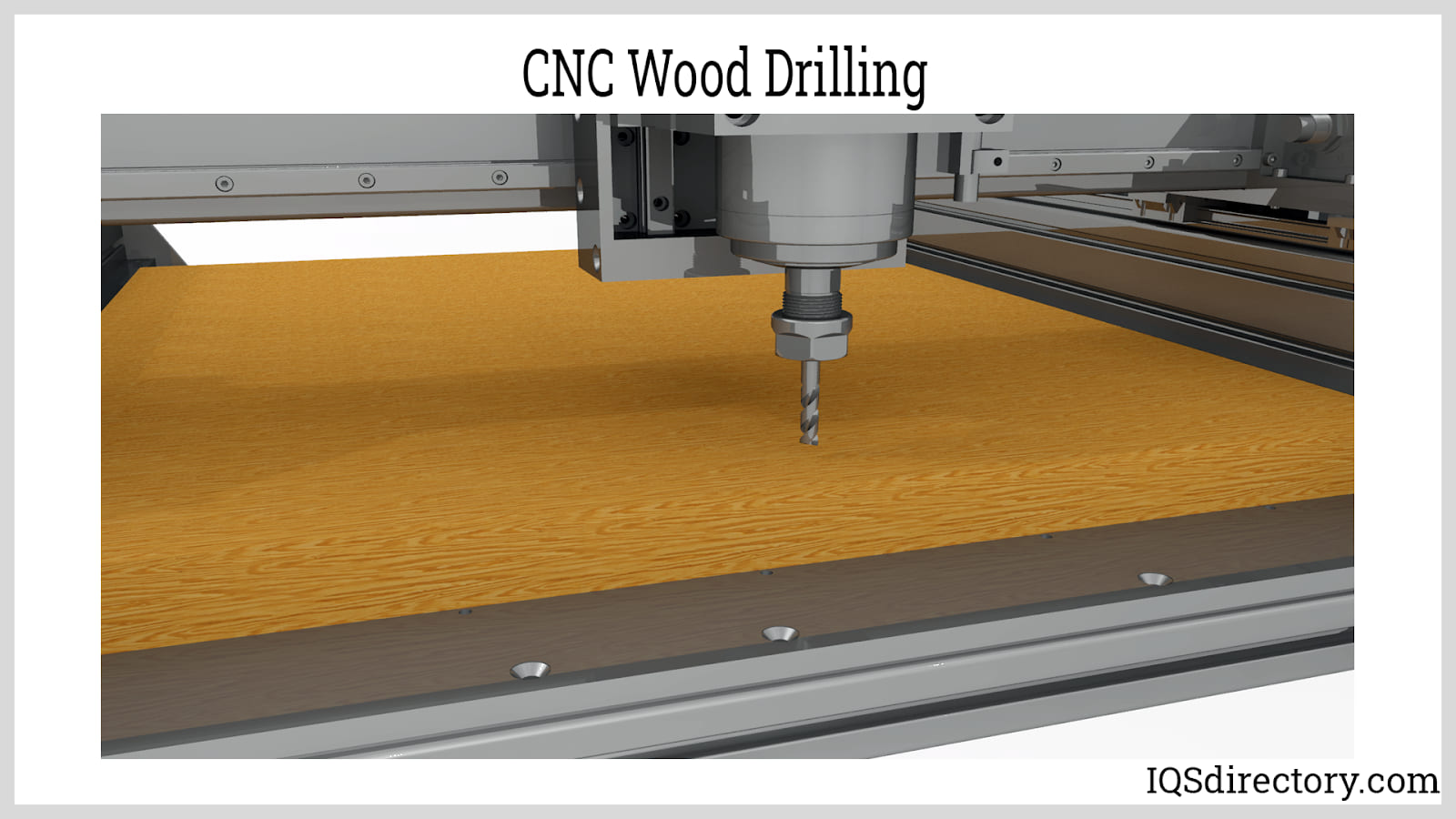

Wood manufacturing

Wood manufacturing is another important application for CNC drilling. The drill is used to shape wooden planks and to do piercings and decorations.

Electronic components

Some highly-precise CNC drilling machines are used to shape microscopic parts with great production rates. With computer programs, the drill can accurately drill without damaging fragile components.

Electrical industry

Some electric components require accurate drilling to be used with electric power transmission. Complex circuit breakers and transformers are typical examples of such items.

Plastic manufacturing

CNC drilling machines are also used to design intricate patterns used in decorative packaging and displays.

Advantages of CNC Drilling

Higher accuracy and precision

CNC technology-based drills can make original designs with very tight edges without wasting resources.

Versatility

CNC drilling is an operation that can be employed with numerous materials ranging from various metals to weaker materials like plastics and nylon. Additionally, numerous drill bits exist to produce various hole types and patterns.

Fewer sub-quality products

Correctly set-up CNC mills are less prone to faults, leading to consistency and uniformity during the production of large-scale orders.

Compatibility with other machining operations

Traditional drilling requires frequent adjustments of various mills and routers and is often performed independently of one another and other manufacturing processes. CNC drilling allows for changes to be performed as a single equipment unit and simultaneously with other procedures of material shaping.

Selecting the Correct CNC Drilling Company

To ensure the most beneficial outcome when selecting a CNC drilling company, it is important to compare several companies using our directory of CNC drilling businesses. Each CNC drilling machine company has a business profile page illustrating their areas of expertise and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each CNC drilling company website using our proprietary website previewer for a better understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services