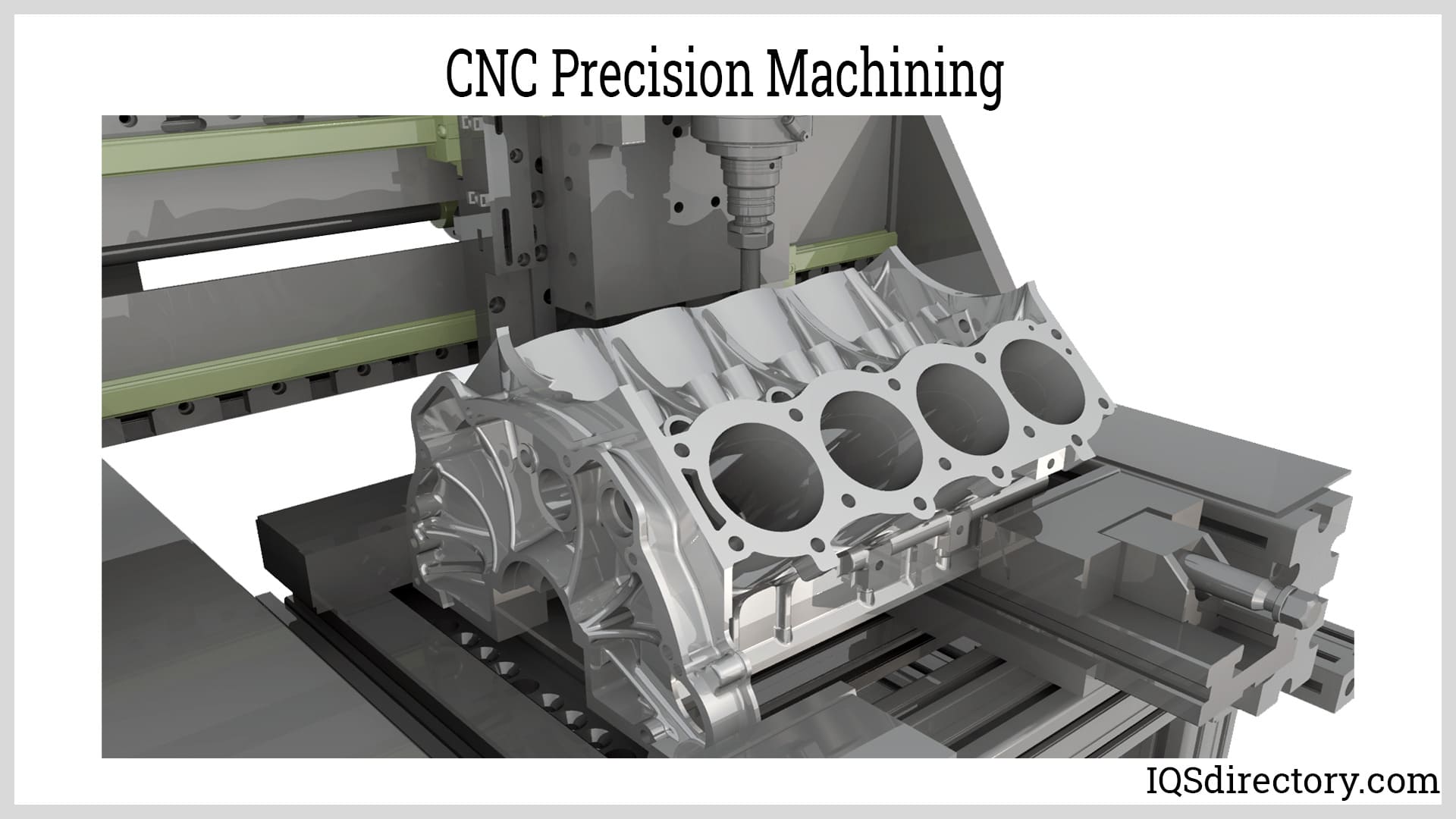

In a machine shop, various machines are used to cut, mold, and shape materials like metal and plastic into unique items. By using machine-operated cutting tools that are programmed by one of the CNC computer programs, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), CNC machines manipulate raw materials. Since these machines are frequently used to cut metal, stone, and other hard materials, they must be powerful. As a result, they need robust and expensive parts. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

H & R is a custom manufacturer of high volume superior parts, providing CNC machining for tight tolerance and also lower volume applications too.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More CNC Machine Shop Manufacturers

Owning a CNC machine is expensive in part due to installation and maintenance costs. A business with production needs may turn to CNC machine shops to complete the task quickly and affordably rather than purchasing expensive CNC machines separately. It is also simple to make arrangements if a business needs specific products in huge quantities, whether standardized or unique.

What to Consider When Using CNC Machine Shops

Knowing the specifications of the necessary machine parts is crucial when using CNC machine shops. During the earliest stages of the process, understanding the technique required or a design plan is helpful. In certain situations, CNC machine shops will develop design codes based on requirements provided to them with bespoke machine work, or they will take an existing item and create design codes based on photo imaging software.

Additionally, a less expensive, ordinary machine may be used to make the particular part that was brought in. In either case, quality is guaranteed if the business has National Institute of Metalworking Skills certification and complies with ISO standards.

Safety in CNC Machine Shops

- Wear the proper attire. A CNC machine shop forbids wearing loose-fitting clothing, flammable clothing, jewelry, and open-toed footwear. Whenever possible, safety shoes should be worn in manufacturing settings. Long hair must be pulled back and hidden by a shirt or cap.

- Wear protective eyewear. Any machine operation should be done while wearing goggles or other eye protection. Removing chips from the workpiece can result in severe harm, and all machines must have cover guards to protect operators' eyes.

- Know the equipment. Only skilled machinists should operate machines. Workers should study the operator's manual before using a new or unfamiliar machine. Finding the switch's placement is important.

- Keep workspaces clean. Dirt can cause slippery surfaces, and a buildup of dust and debris can cause respiratory illnesses.

Applications Of CNC Machine Shops

Although additional services, such as polishing and painting, are sometimes provided by machine shops, very little "finishing" to eliminate rough edges or flaws is required when using CNC machining.

Machine shops serve a wide range of industries, including:

- Defense Industry: In the defense industry, an accelerated demonstration prototype might be used as proof of concept for a new kind of sensor on a fighter jet rather than the entire aircraft. An accelerated demonstration aims to demonstrate the functionality of novel ideas, concepts, or systems. CNC machining is frequently responsible for these separate parts or subsystems. These components and ideas can be shown at significant time and cost savings due to the quick turnaround for machining.

- Automotive Industry: CNC machining enables substantially faster manufacturing times than conventional machining. Since the procedure is mechanized, human limitations like weariness are not an issue. In addition, the method works best for making large quantities of a part quickly since the computer instructions can be repeated as often as required.

- Medical Industry: High-quality surgical instruments, parts for medical equipment like pacemakers, and even surgically implantable gadgets can all be created using CNC machining. For instance, bone screws are an ideal component to be produced by a Swiss CNC machine. To prevent patient discomfort and even part failure, these screws must have clean surfaces and extremely tight tolerances of as low as one millimeter in one direction. Due to contamination concerns, fluid cutting is not an option for making them; therefore, CNC machining is the only method available. In addition, Swiss machining is the ideal technique for cutting a product with a significant length-to-width ratio.

Advantages of CNC Machine Shops

CNC grinding, which uses an abrasive wheel, disc, or belt to provide automated precision material removal and surface quality, is only one of the intricate tasks that CNC machine shops offer. Other services provided by machine shops include:

- Milling: Using rotating multi-point cutting tools and digital controls, CNC milling gradually removes material from the workpiece to create a specific part or product tailored to the customer's needs. This method is appropriate for cutting various custom-designed parts and products from various materials, including metal, plastic, glass, and wood.

- Cutting: Using a CNC router, materials may be quickly and precisely sliced or engraved. It can cut materials including plastic, foam, wood, composites, and acrylic, just like laser cutters, and is excellent for precisely cutting steel, aluminum, and other metal plates.

- Precision machining: This is the process of cutting different materials to precise measurements. Typically, this procedure entails trimming superfluous material off a metal component (or other material) and reshaping it to a precise tolerance.

Choosing the Right CNC Machine Shop

To ensure the most productive outcome when selecting a CNC machine shop, it is important to compare several CNC machine shops using our directory of CNC machine shops. Each shop has a business profile page highlighting their areas of experience and capabilities, as well as a contact form to directly communicate with them for more information or request a quote. Review each CNC machine shop website using our patented website previewer to get an idea of what each company specializes in. Then use our simple RFQ form to contact multiple businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services