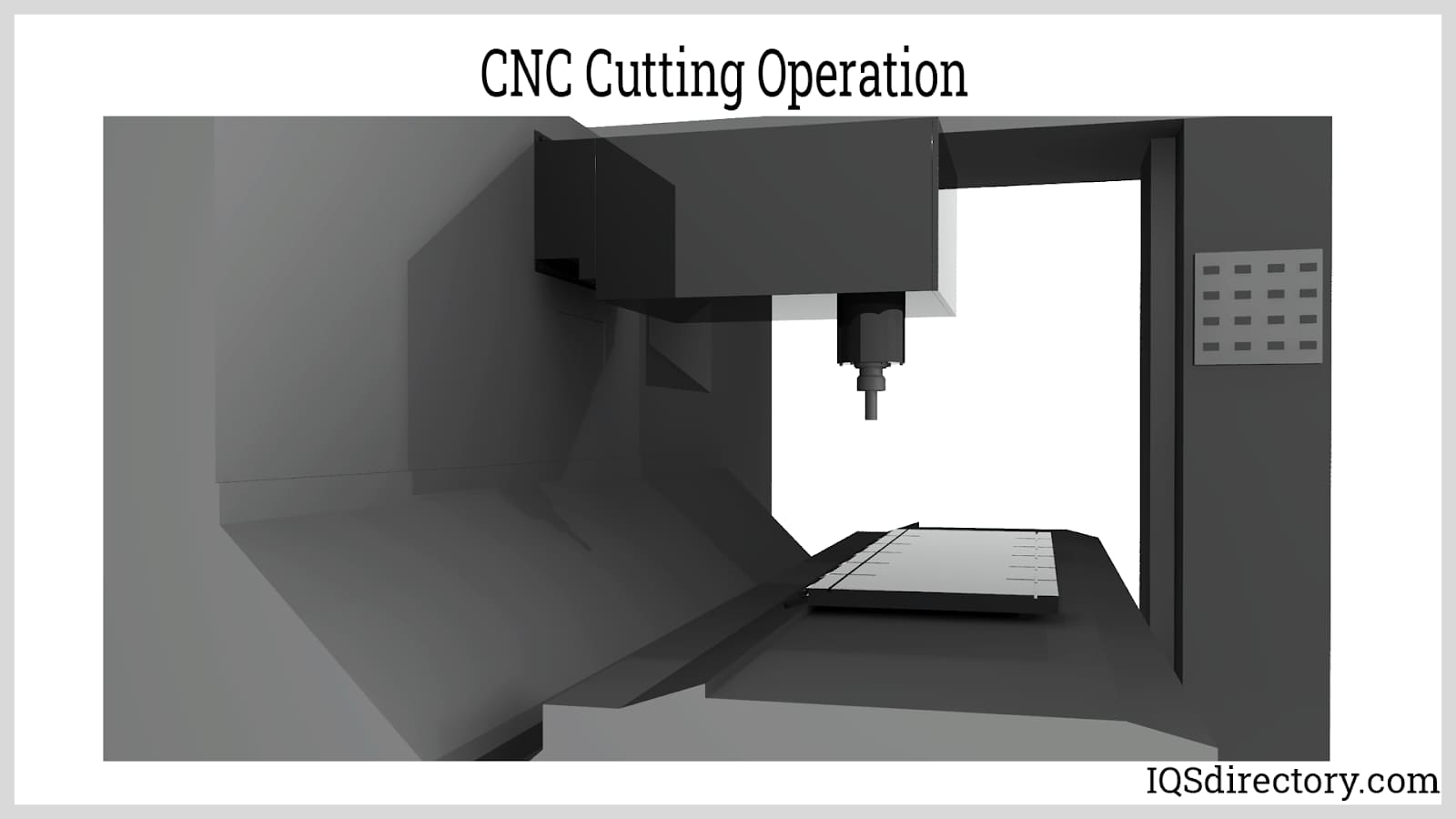

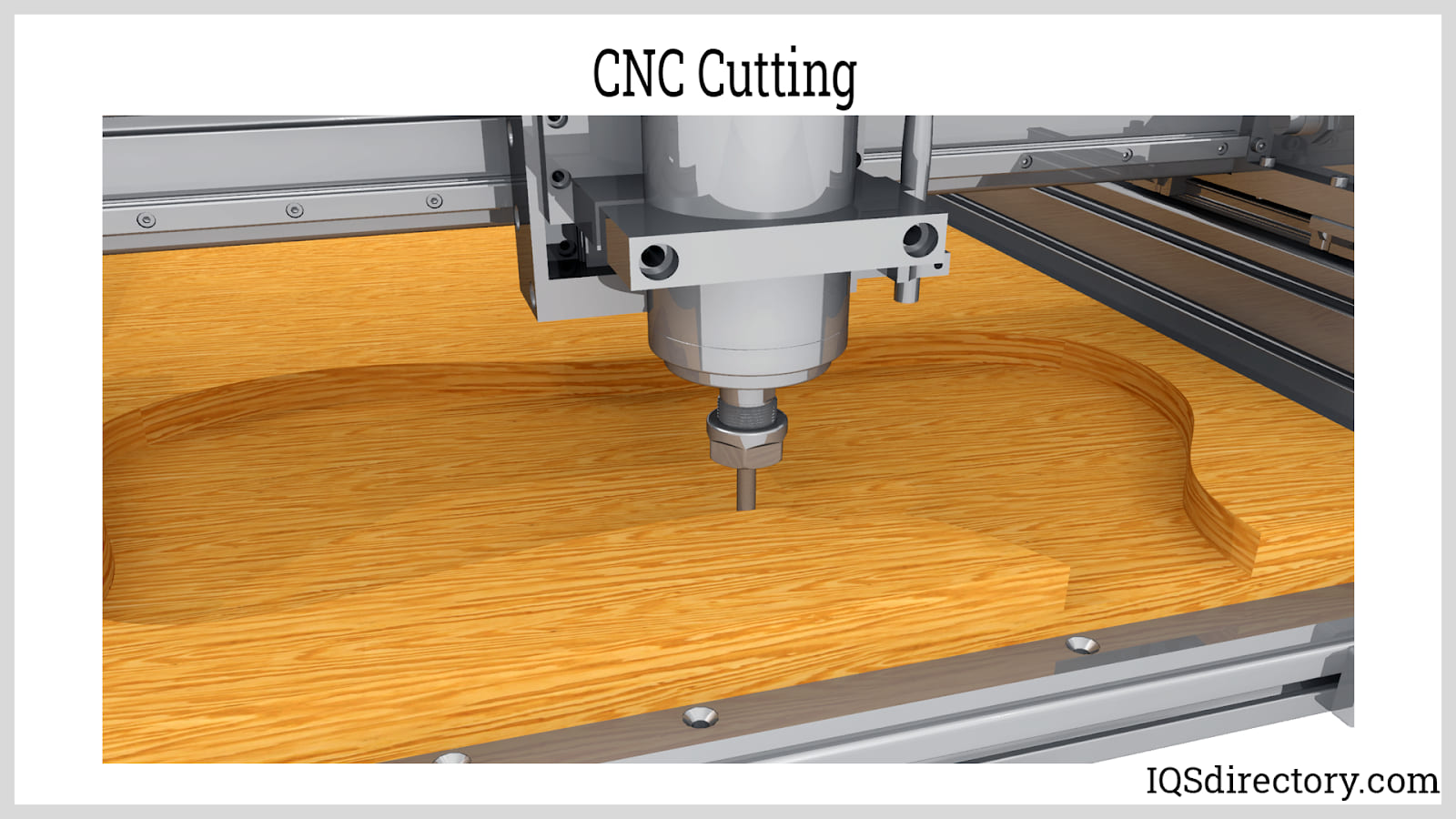

CNC cutting refers to computerized controls paired with cutting tools to obtain an accurate and precise cut finish. It is used in industrial situations where mass production is the objective and the materials produced are needed to have very few faults and contain inaccurate or irregular shapes. Machine shops and mass production facilities in a broad range of industrial and commercial settings, including aerospace, avionics, automotive, agriculture, food and chemical processing, pharmaceutical, military, and defense, utilize this particular type of machining in daily operations. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

H & R is a custom manufacturer of high volume superior parts, providing CNC machining for tight tolerance and also lower volume applications too.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More CNC Cutting Manufacturers

How CNC Cutting Machines Work

Firstly, the program of the desired part is loaded into the MCU (machine control unit) of the CNC (computer numerical control). The program's data is read, and the commands are executed to the driving system. If there are any errors or mistakes inside the MCU, signals are sent to correct and restructure the components to where they are supposed to be. A display panel acts as the user interface and shows the user-executed instructions or commands to be executed.

Types of CNC Cutting Machines

The types of CNC cutting machines include:

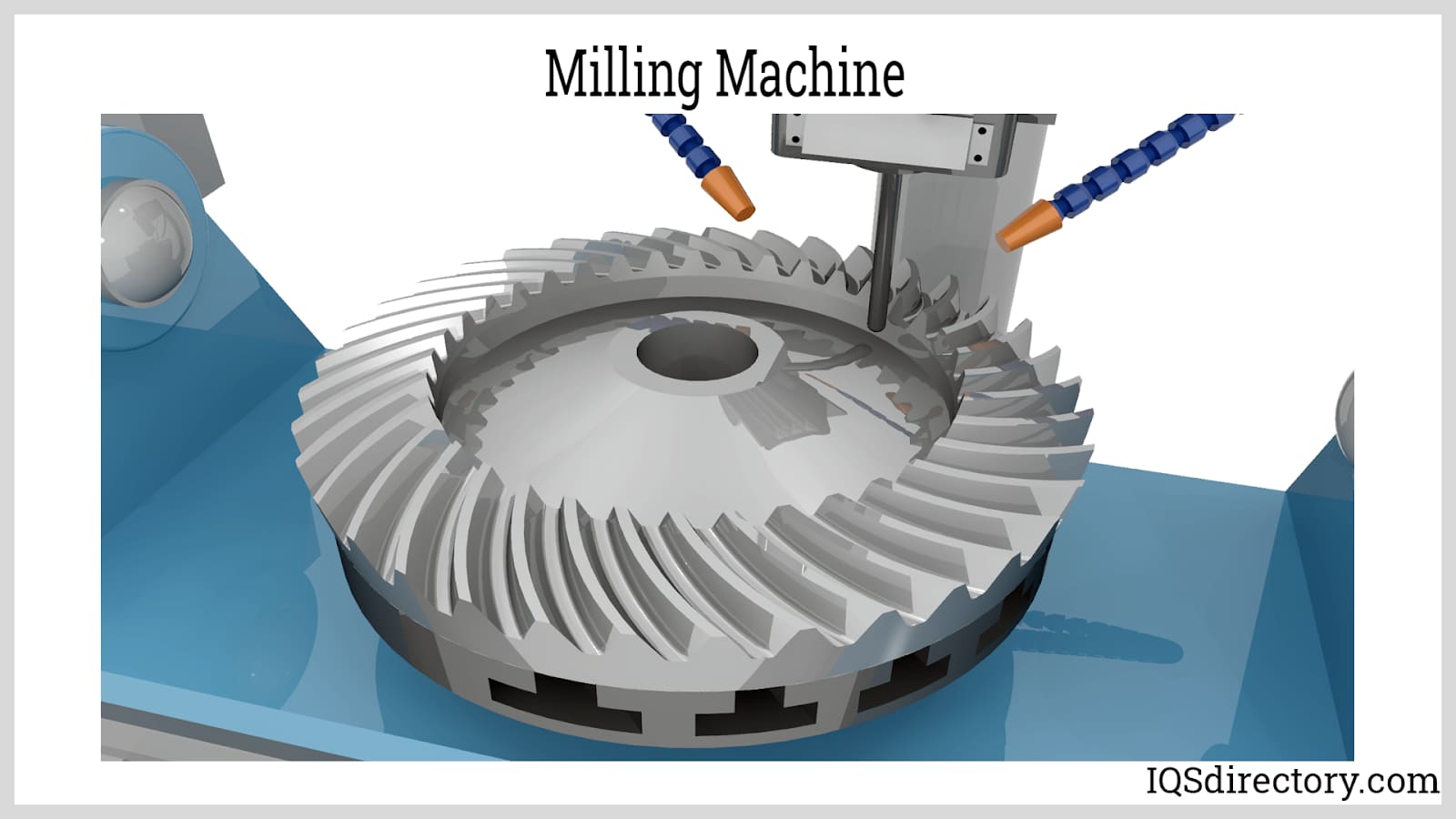

Milling Machines

Milling machines are the most popular CNC cutting machines and feature a multi-blade cutting mechanism. The blades are attached to a spindle and are rotated at high speeds on a stationary workpiece. They are ideal for angle cuts and complex cuttings, and they can work on metals and other materials such as plastics and wood.

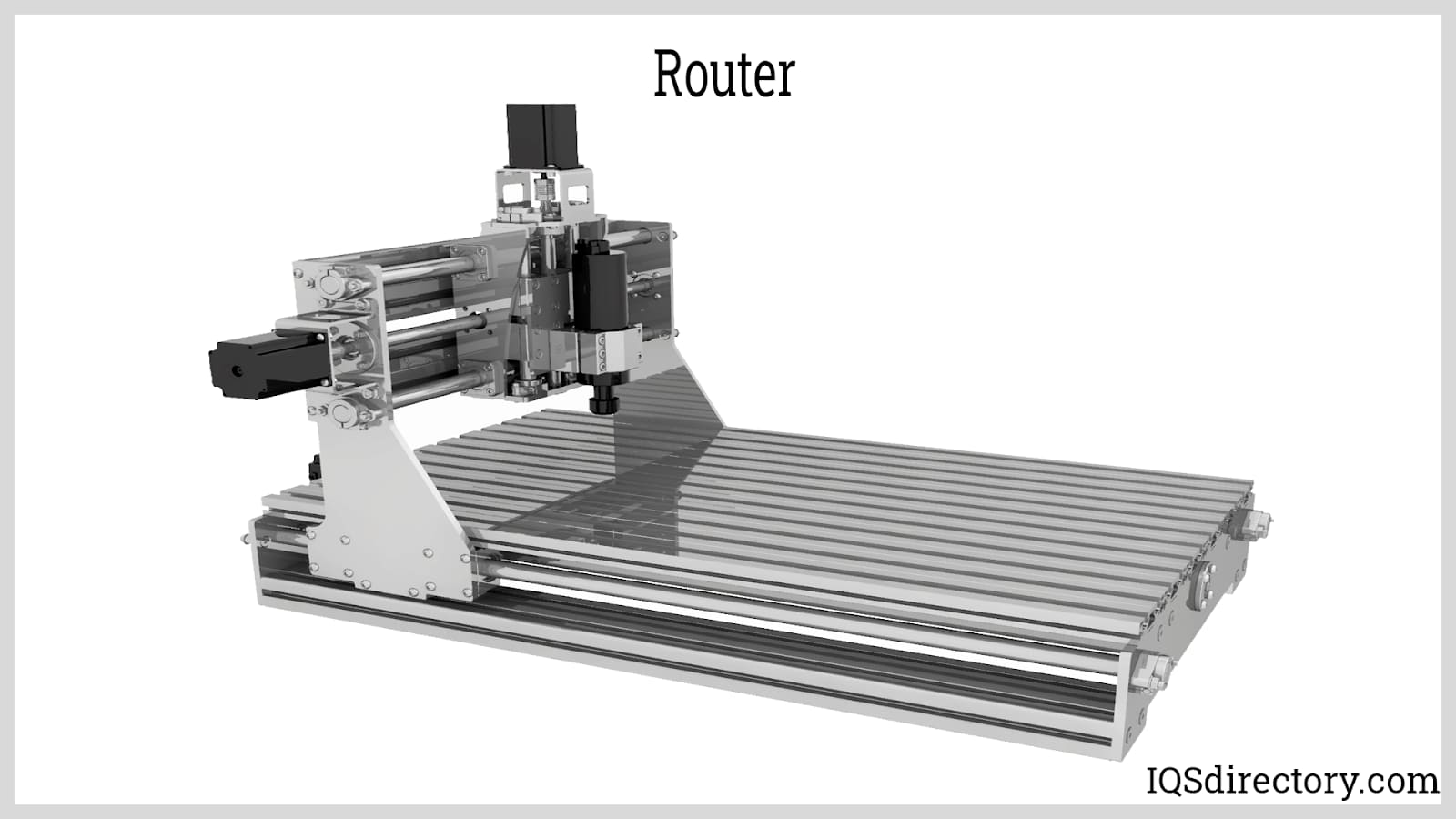

Routers

CNC routers are similar to CNC mills as they also use a multi-blade system on a stationary workpiece. They, however, are commonly used on softer and more delicate materials such as wood, foam, and plastic.

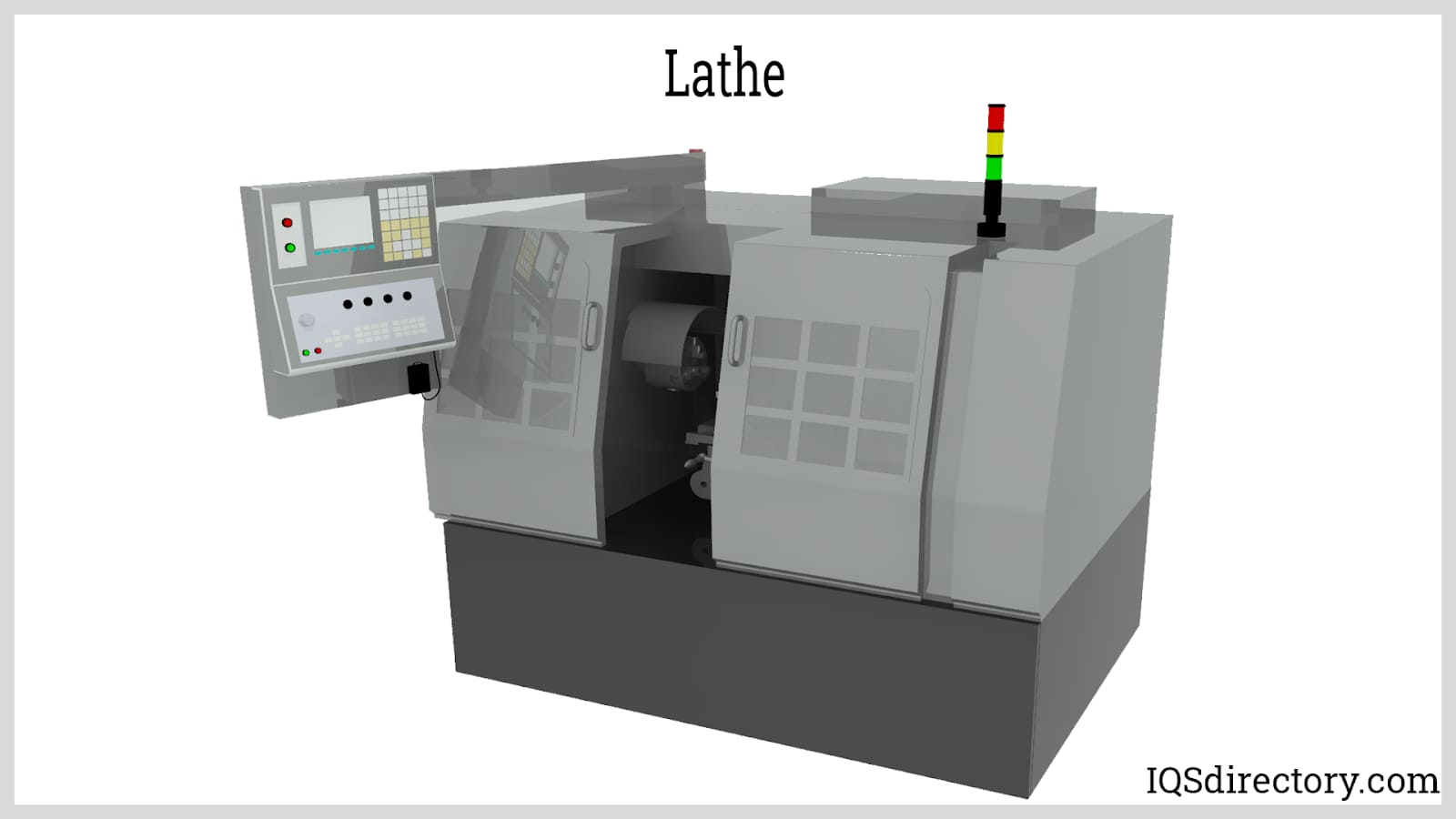

Lathes

CNC lathes are also derived from CNC mills and routers. They comprise a chuck and spindle that depends on CNC technology. In CNC lathes, the spindle and chuck hold and spin the workpiece on the cutting tool. They are commonly used on complex cylindrical shapes.

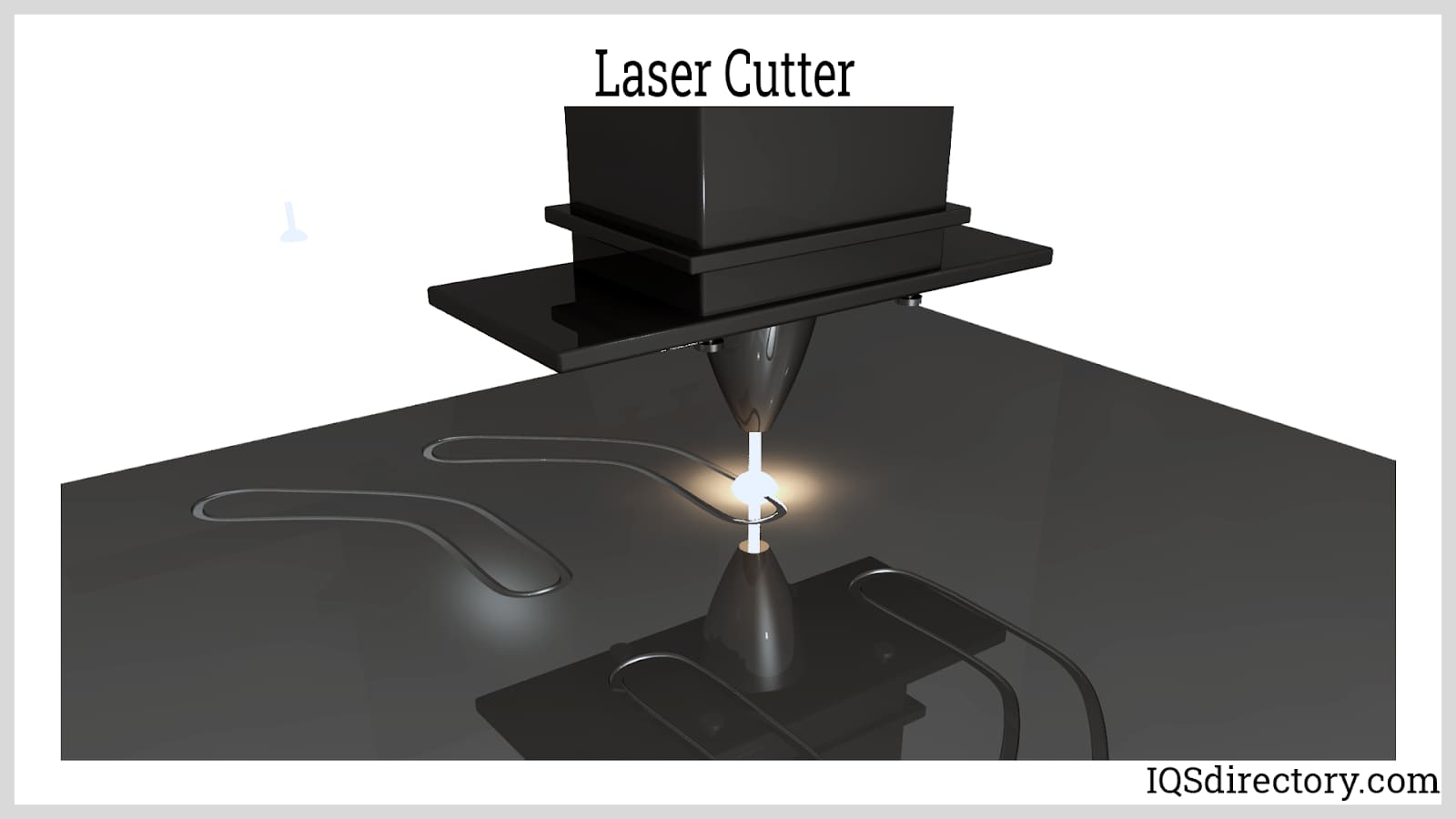

Laser Cutters

Laser cutters are closely related to mills in the types of materials they can machine. The difference is that laser beams are used in this cutting machine. A laser is essentially a column of intensified light. When this light is directed at a workpiece, it melts that object until a cut is produced.

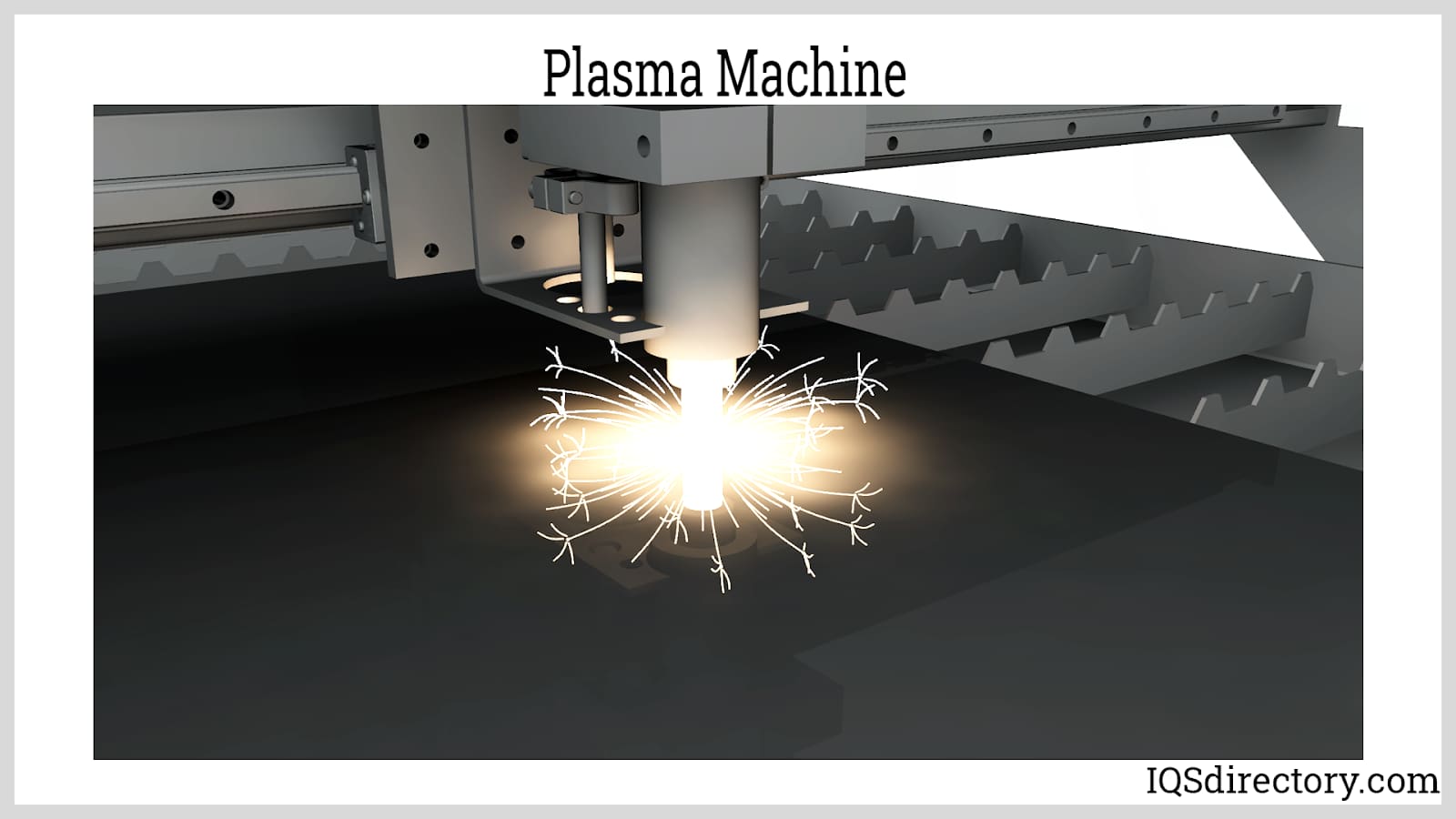

Plasma Machines

Plasma machines offer a higher level of cutting precision and a wider range of material compatibility. They produce high-powered plasma that reaches very high temperatures. This plasma can cut through any material that can conduct electricity.

Electrical Discharge Machines

CNC electrical discharge machines are called spark machines because they use electric sparks to cut materials. To function, the material to be cut must also be a good electric conductor.

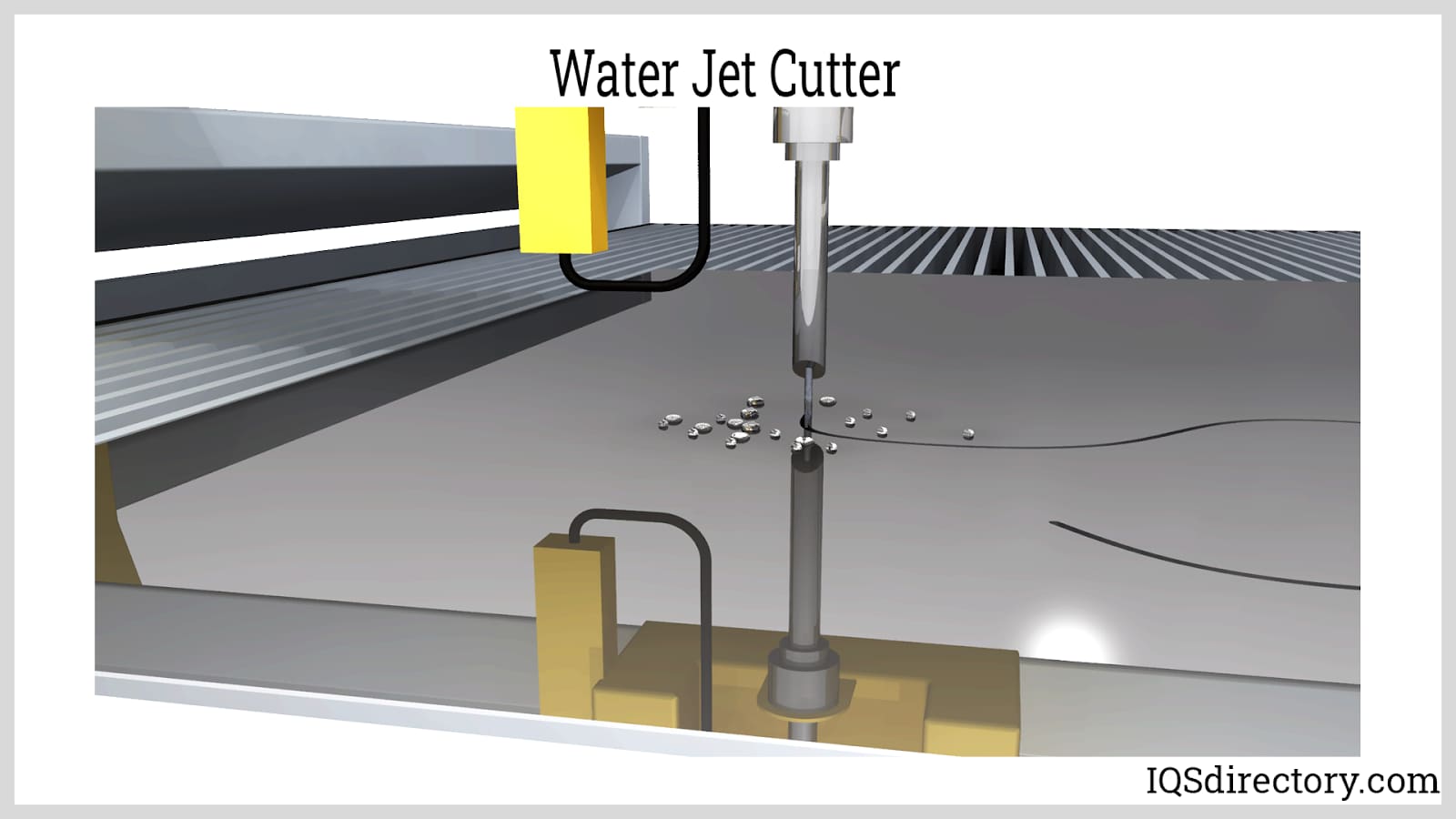

Water Jet Cutters

A CNC water jet uses a pressurized jet of liquid mixed with an abrasive substance to make piercings and cuttings on materials. The CNC technology employed controls the sequence and movement of the jet to obtain the desired cut.

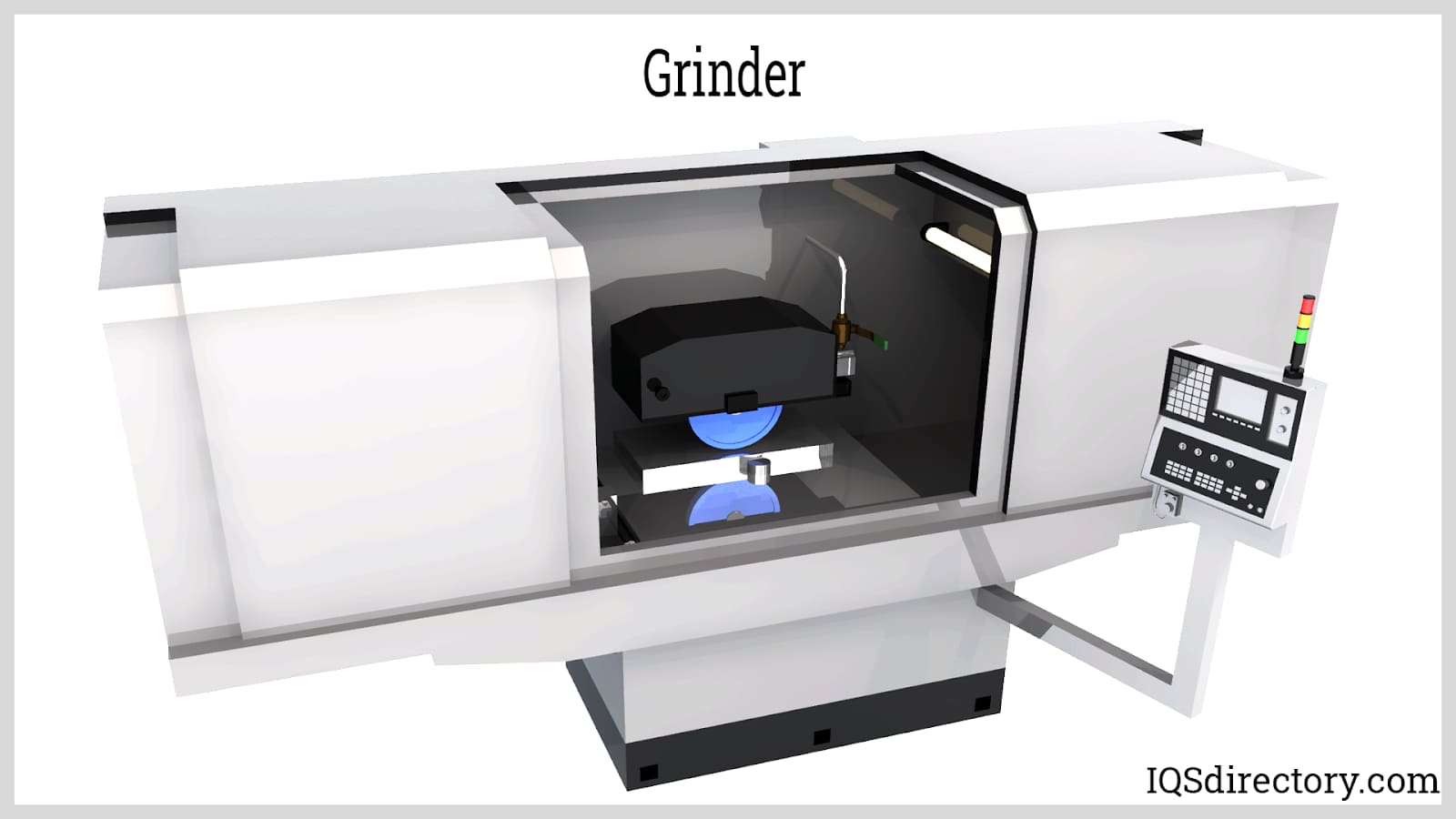

Grinders

CNC grinders have rotating wheels that cut materials from the workpiece to make the required product. These machines have intelligent thermal control systems that monitor the temperature of the grinding wheel and compensate for any changes that arise.

Applications of CNC Cutting

Dental Equipment

Dentists use CNC tools because these machines help produce perfect finishes with accurate cuttings. CNC tools help maintain the high precision required in dentistry.

Weapons

The manufacture of weapons and military-grade equipment is made easy by CNC machines since they produce grade A, top-notch weapons with minimum defects.

Construction

Plumbers, fitters, carpenters, and other tradespeople require the use of CNC cutting machines for perfect finishes on construction materials.

Transportation

Designing and manufacturing transportation equipment requires utmost diligence and accuracy. These designs can be easily achieved by CNC cutting machines.

Research and Development

Modern industries increasingly design and produce prototypes for cost-saving trial runs before mass producing their goods. These prototypes are quickly and cheaply constructed with the use of CNC machines.

Niche Manufacturing

CNC cutting is easily adopted in any manufacturing process. It can be used to speed up the process and complete it with minimal loss and expense.

Advantages of CNC Cutting

- CNC cutting creates products with little or no waste.

- It offers greater accuracy.

- It results in faster and more efficient production.

- CNC cutting provides improved worker safety.

- Production costs are lowered with CNC cutting.

- There is a reduction in energy consumption.

- CNC cutting produces items with fewer defects.

Choosing the Proper CNC Cutting Company

To ensure the most positive outcome when using a service from a CNC cutting company, it is important to compare several companies using our list of CNC cutting businesses. Each CNC cutting company has a business profile page highlighting their areas of expertise and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each CNC cutting business to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple CNC cutting businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services