Custom machining is a process whereby materials are machined to meet a customer’s requirements. Custom machining is part of the CNC machining process. In this type of CNC machining process, operators create new parts with the help they get from different forms of CNC machining. Custom machining is utilized when there is a need for a specific part that is not available in a machine shop or when there is a special requirement for a common part. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

H & R is a custom manufacturer of high volume superior parts, providing CNC machining for tight tolerance and also lower volume applications too.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More Custom Machining Manufacturers

For these purposes, custom machining exists- creating specialized parts or customizing a standard part. Custom machining is not only utilized for the manufacturing of smaller parts but also for creating large parts with unique features. These parts are customized so that they fit well for a specific project.

Why is Custom Machining Necessary?

- The needed item is incompatible and not offered by a supplier, necessitating special machining.

- The requested part has special characteristics not present in conventional parts.

- There are times when it may be necessary to merge many components into one.

- In a crisis, speedy production of high-quality components is possible through custom machining.

- Custom machining makes it possible to produce components when only a few parts are needed.

Detailed Process for Custom CNC Machining

In the field of engineering, custom CNC machining has advanced significantly. Where CNC machine shops traditionally utilized punched tape cards in the past, today's CNC manufacturers employ computer-controlled machinery to carry out a variety of CNC machining procedures on a workpiece, including cutting, sawing, broaching, lapping, honing, and drilling. Regardless of the complexity achieved using this CNC machining, the basic procedure, in the following order, stays the same:

- The computer-aided design (CAD) model is produced by the design engineer using pertinent software.

- When input into the system, a set of CNC programs is created from the design.

- These computer instructions are given to the CNC machine.

- The CNC machine uses these programs to design the final component of the workpiece.

Types of Custom Machining

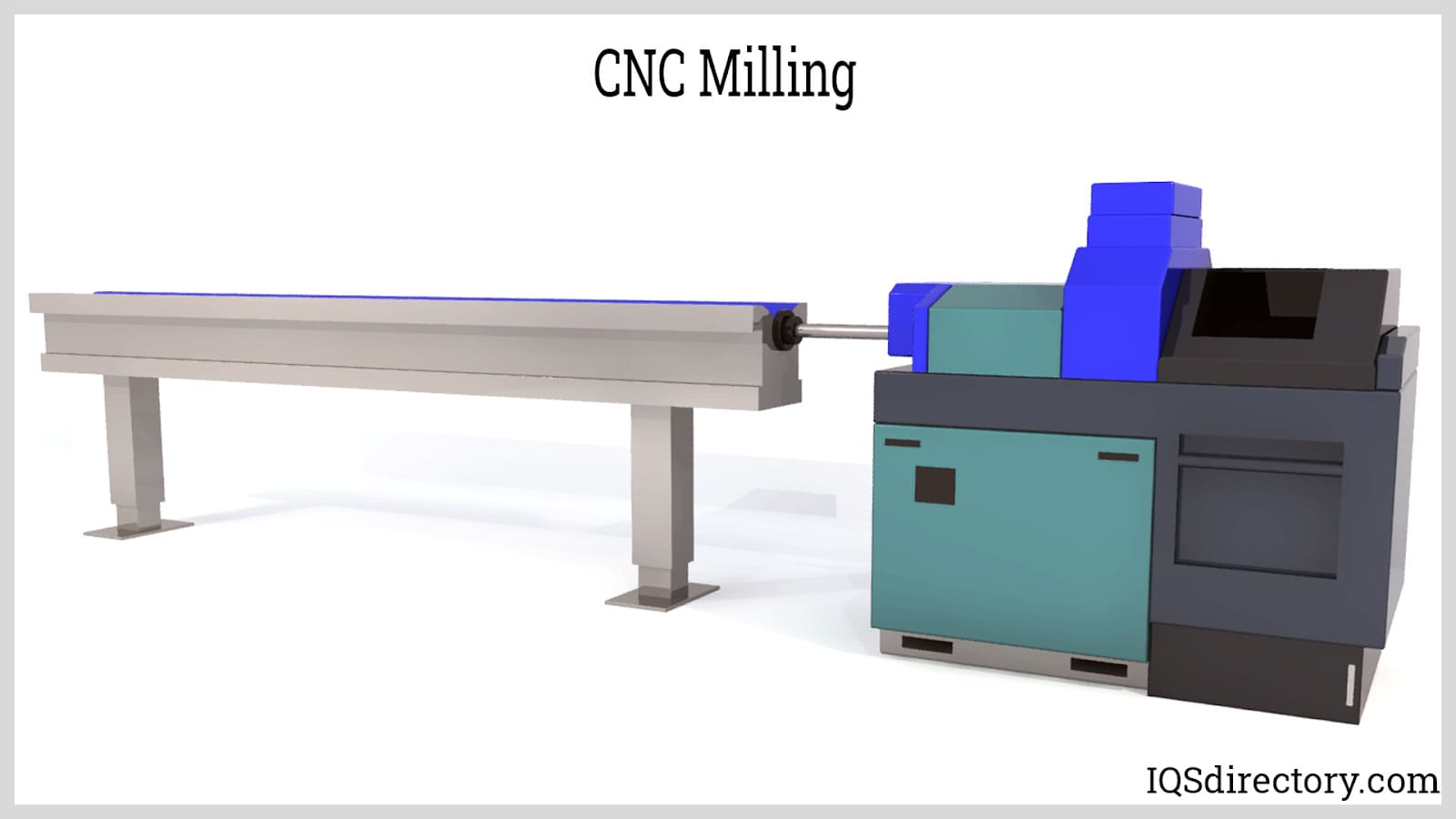

CNC Milling

CNC milling is used by machinists when they need to turn, as well as drill, metals. CNC milling is one of the very common types of custom machining services. This custom machining service uses a block of material to form parts. Then, the material is milled until the formation of the end product.

Manufacturers can also use this milling process on plastic and other products. In addition, milling machines utilized in traditional machining can be retrofitted to be used for CNC machining services. After their transformation, that may be how they are mostly used.

CNC Turning

CNC turning is another common process that is utilized through custom machining. During this process, a metal rod is rotated with the help that comes from a CNC-operated cutting tool. This tool functions to remove parts of the metal to create a final product. The final product from this process can be left as is or blasted to create a more finished appearance. CNC lathes are best for creating 3D shapes or molds. During the cutting of the materials, the computer turns and controls them. In addition, CNC lathes increase accuracy, which is always a potential issue when using a manual lathe.

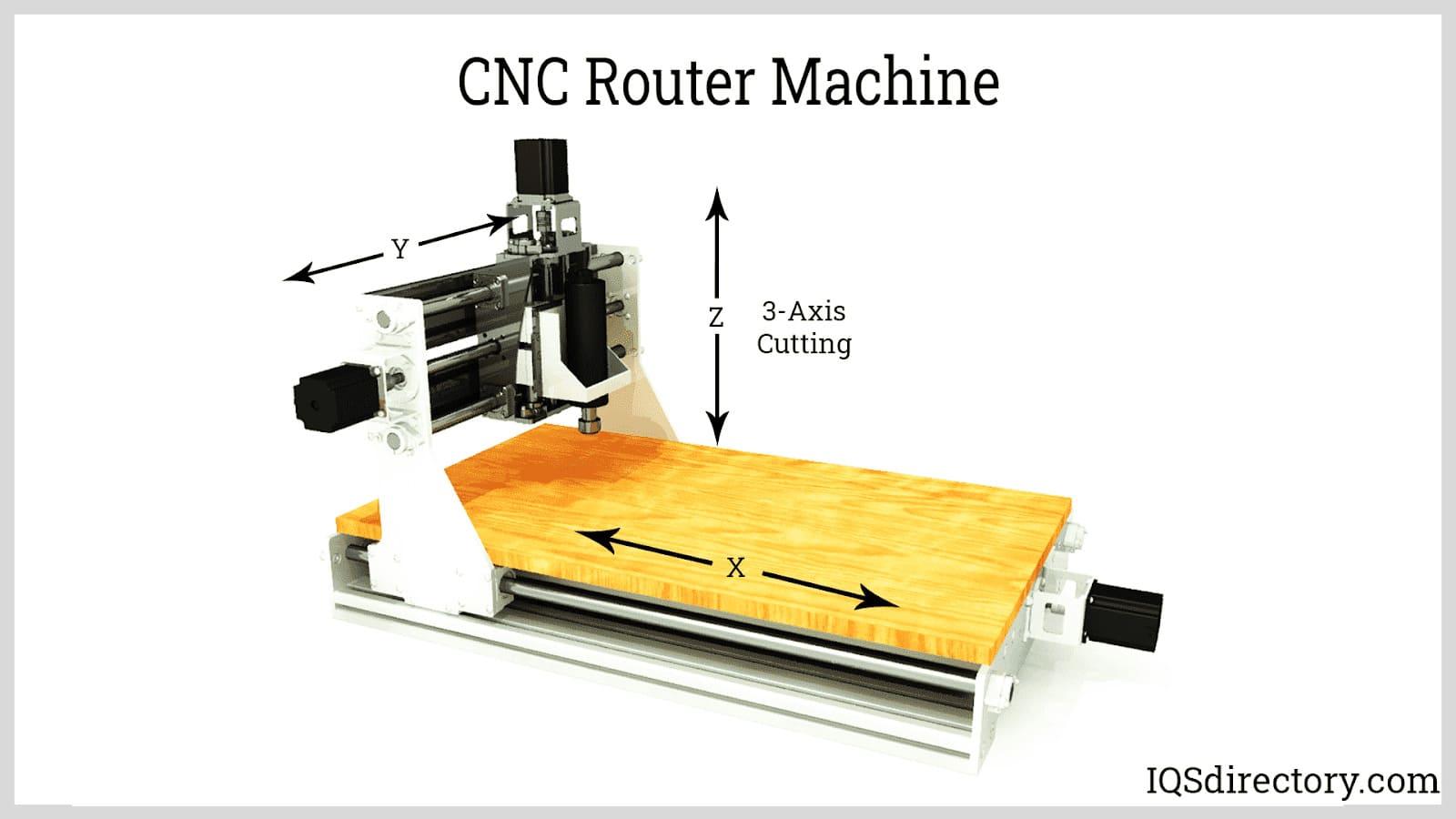

CNC Router

Custom machining through the use of a CNC router is responsible for the cutting of complex pieces of metal sheets. CNC routers can also use with composite materials, foams, glass, and plastics. CNC routers are typically most suitable for large-scale custom machining services. For example, they make moldings, frames, furniture, wood boards, panels, and musical instruments.

Companies use CNC routers for product development, prototyping, and production. Individuals may also utilize CNC routers for hobby work.

Applications of Custom Machining

- Custom machining is used in the aerospace industry for producing precise parts.

- Custom machining is utilized in the agricultural industry.

- The automotive industry also utilizes custom machining to produce various parts.

- Custom machining is used in the construction industry.

Finishing of Custom Machining Components

The following is a partial list of some finished parts produced through custom machining:

- Surgery equipment

- Screws

- Frames for automobiles

- Hydraulic elements

- Airplane engines

- Shafts

Benefits of Custom Machining

Custom machining has the following benefits:

Machine Shops can Work With Difficult Materials.

Some materials cause problems during their traditional production process. Plastic is an example of one such material that needs custom CNC machining equipment. Certain metals, such as stainless steel and bronze, also require custom parts and equipment. Machine Shops cannot use standard production processes with these materials because manual machining equipment will not typically achieve the desired production rates. It is in these situations where custom machining is used best.

High-Precision and High-Quality Parts

Custom machining works better than traditional manufacturing methods for items requiring very demanding standards. As a computerized system, CNC machining can produce parts with a higher level of precision. Additionally, custom machining helps to ensure that the last item produced is created to the same standards as the first item produced.

Fabrication of Parts With Custom Requirements

There are special situations when equipment requires custom-fabricated parts. These situations may include quick turnaround projects requiring additional parts and supplies. Custom machining is the solution when projects request unique parts that are not available in the manufacturers' catalogs but are quickly needed.

One-Time Production Runs

The CNC machine used in custom machining follows pre-set instructions. These instructions, in turn, reduce the chances of errors during the creation of machined parts so that less time and fewer production runs are required.

Choosing the Right Custom Machining Business

For the most positive outcome when choosing a custom machining company, it is important to compare several businesses using our directory of custom machining companies. Each custom machining company has a business profile page highlighting their areas of expertise and capabilities, and a contact form to directly communicate with them for more information or request a quote. Review each custom machining business website using our patented website previewer for an idea of what each business specializes in. Then, use our simple RFQ form to contact multiple custom machining companies with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services