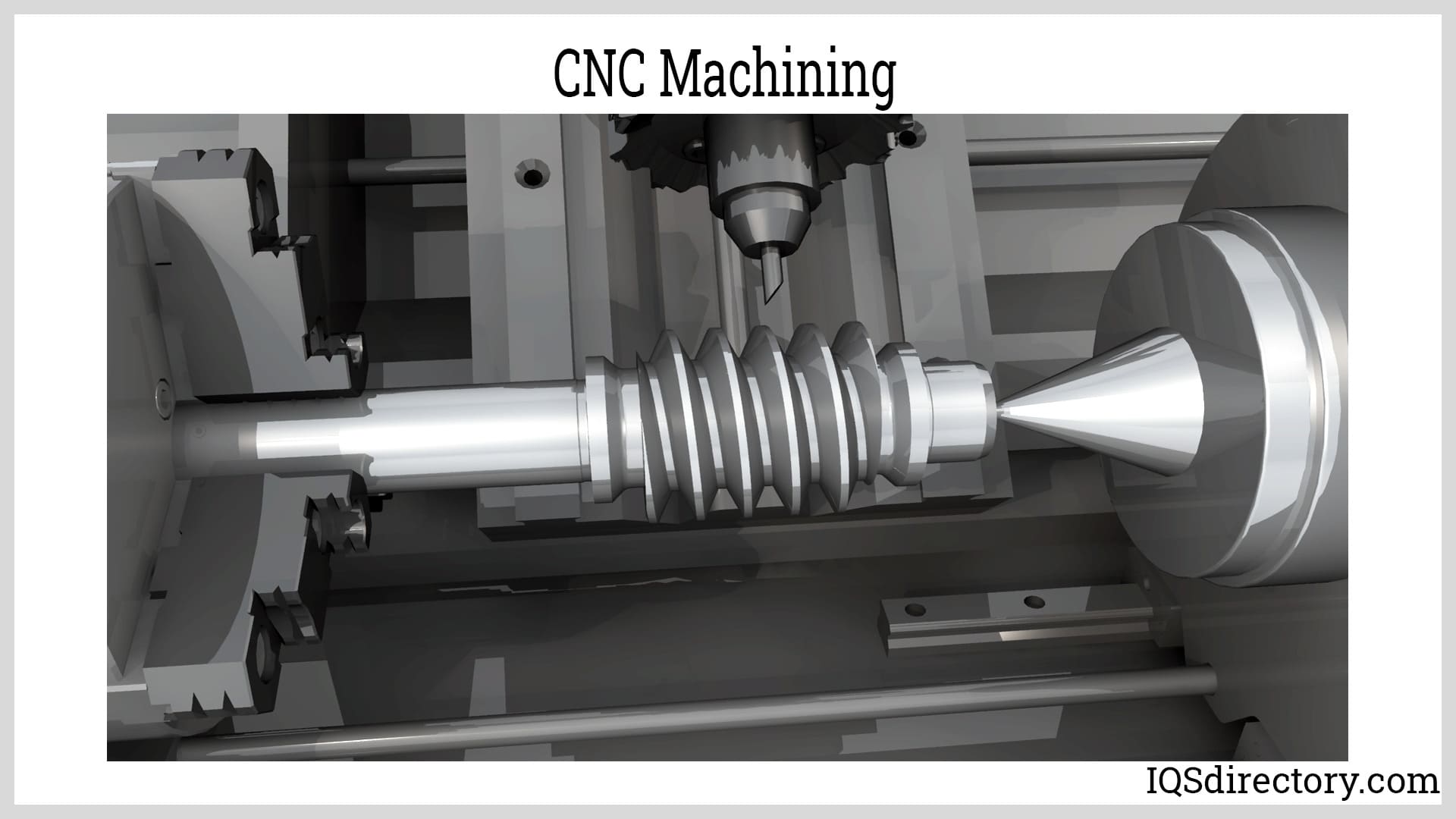

CNC machines encompass most machining tasks. CNC machining is a subtractive manufacturing process that uses computerized controls and machine tools to remove layers of material from a workpiece to produce a custom-designed part. Materials, including metals, plastics, wood, glass, foam, and composites, can all be machined. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

H & R is a custom manufacturer of high volume superior parts, providing CNC machining for tight tolerance and also lower volume applications too.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More Machine Work Manufacturers

CNC Machining Process

Computer Programming

Initial programming is essential for successful CNC manufacturing. The software must be programmed with the correct directives to keep the machine operating within its capabilities. The person who writes the instructions for CNC machinery determines the processes. The coded instructions are carefully created to prevent mistakes and lost manufacturing time.

CAD and CAM

The software used to design and create parts and components using a CNC machine is known as CAD-CAM. CAD software designs, sketches, produces, and shapes parts using geometric constructions and shapes. CAM converts CAD data into G-Code, a machine language from which parts may be manufactured. The CAM software chooses the cutting paths for the tools to remove extra material from the workpiece before translating the CAD-designed model into machine language. Together, CAD and CAM give the CNC machine the precise instructions to carry out the required cutting operations.

Types of CNC Machining

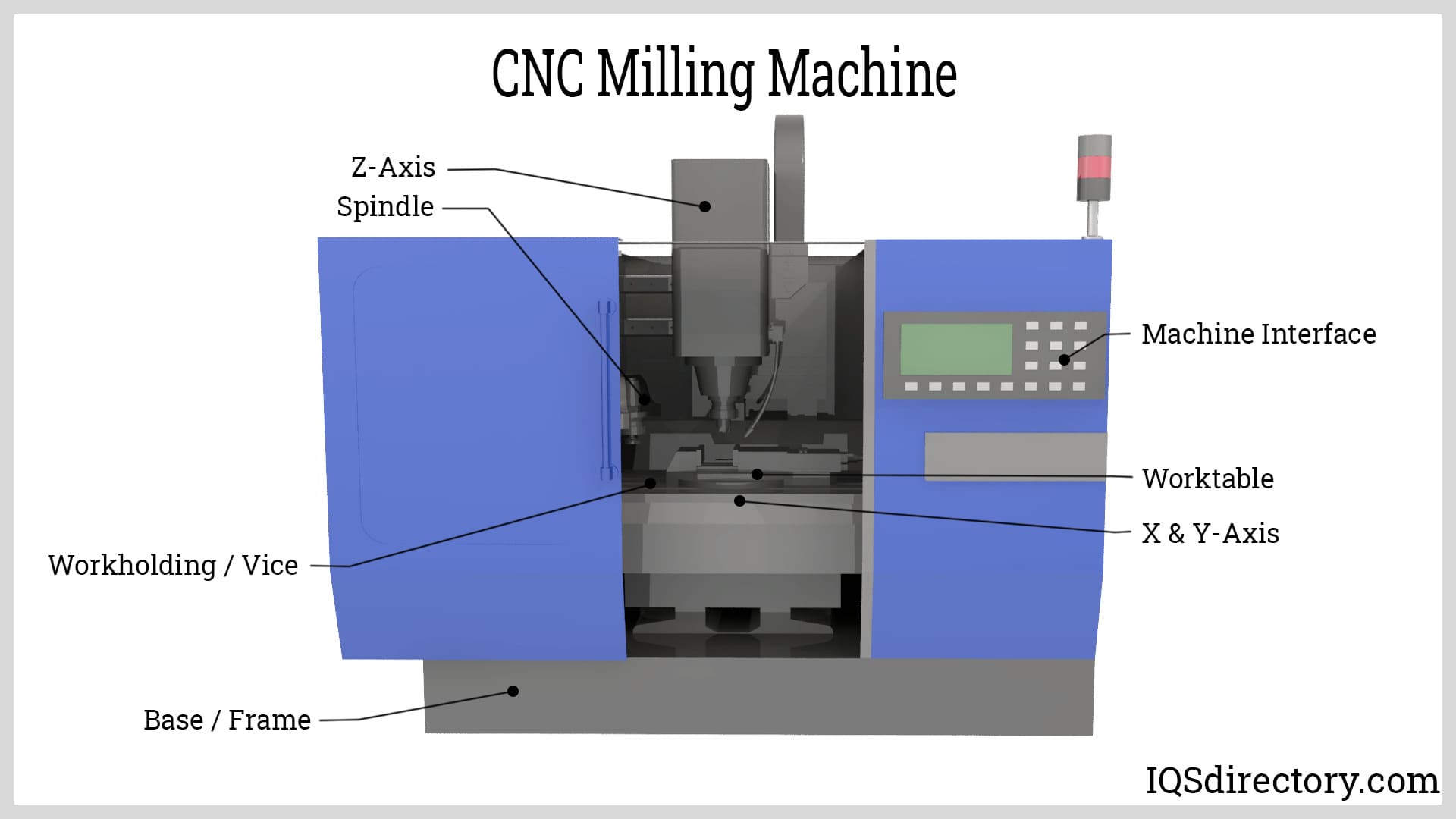

CNC milling

To transform the material into a mechanical part, a CNC milling machine moves a spinning cylindrical cutter along many axes while cutting slots, holes, and other details into the material. Most machines use three to five axes, which results in far more precision and detail. Modern CNC milling machines can be built as vertical or horizontal machining centers. In addition to using metals, CNC machines can shape plastic, ceramic, and composites. For machines to operate efficiently without human intervention, technical elements, including automatic tool changers, tool carousels & magazines, coolant systems, and enclosures, are used.

Types of Milling Machines in Machine Work

Face Milling

Machining a flat surface perpendicular to the cutter's axis is known as face milling. This procedure uses cutters with teeth on the tool face and tool perimeter. Each pair of teeth performs a specific task, with the face teeth finishing while the peripheral teeth perform cutting. Face milling can be used for vertical or horizontal procedures and creates finishes of superior quality.

Plain Milling

When the milling cutter axis is parallel to the milling surface, it is known as plain milling, surface milling, or slab milling. The cutter is mounted on a typical milling machine arbor, and the workpiece is positioned such that it is parallel to the table's surface. The milling machine spindle and one or more arbor support hold the arbor in a horizontal plane—directly clamping the workpiece to the table. Simple milling tools have teeth around the cutting tool's edge.

Whereas wide cutters are used for vast surfaces, and narrow cutters are used for deep cuts, both can produce the part's approximate geometry when significant amounts of material need to be removed from the workpiece. The operator first uses a coarse-toothed cutter, slow cutting speeds, and fast feed rates.

This is followed by a finer-toothed cutter, faster cutting speeds, and slower feed rates for the details. In a CNC machine, drilling is typically carried out with the workpiece perpendicular to the drill bit. Different-sized drill bits are used to create different kinds of cylindrical holes. On specifically constructed machines, drilling along non-perpendicular axes can be carried out.

CNC Waterjet Machining

A water jet is a type of CNC machining that removes extra material from the workpiece using water under high pressure and an abrasive. Even though water under pressure has the potential to cut a variety of materials on its own, abrasives like garnet and aluminum oxide can be added to the water to boost its cutting power, especially for tough materials.

CNC Turning

When turning a workpiece, single-point cutting tools are used to remove material from the rotating workpiece. A CNC lathe machine feeds the cutting tool in a linear motion along the surface of the rotating workpiece to produce cylindrical pieces with exterior and internal features, such as slots, tapers, and threads. Up till the target diameter is attained, this process is repeated.

The operational capabilities of the turning process include boring, facing, grooving, and thread cutting. Comparing the CNC mill to the CNC lathe, the CNC mill performs better for more complex components due to its rotating cutting tools. On the other hand, lathes manufacture round objects more rapidly and accurately because of its rotating work parts and fixed cutting tools.

Choosing the Right Machine Working Company

For the most productive experience when selecting a machine working company, it is important to compare several businesses using our directory of machine working businesses. Each company has a business profile page highlighting their areas of expertise and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each business website using our patented website previewer for an understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple machine working businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services