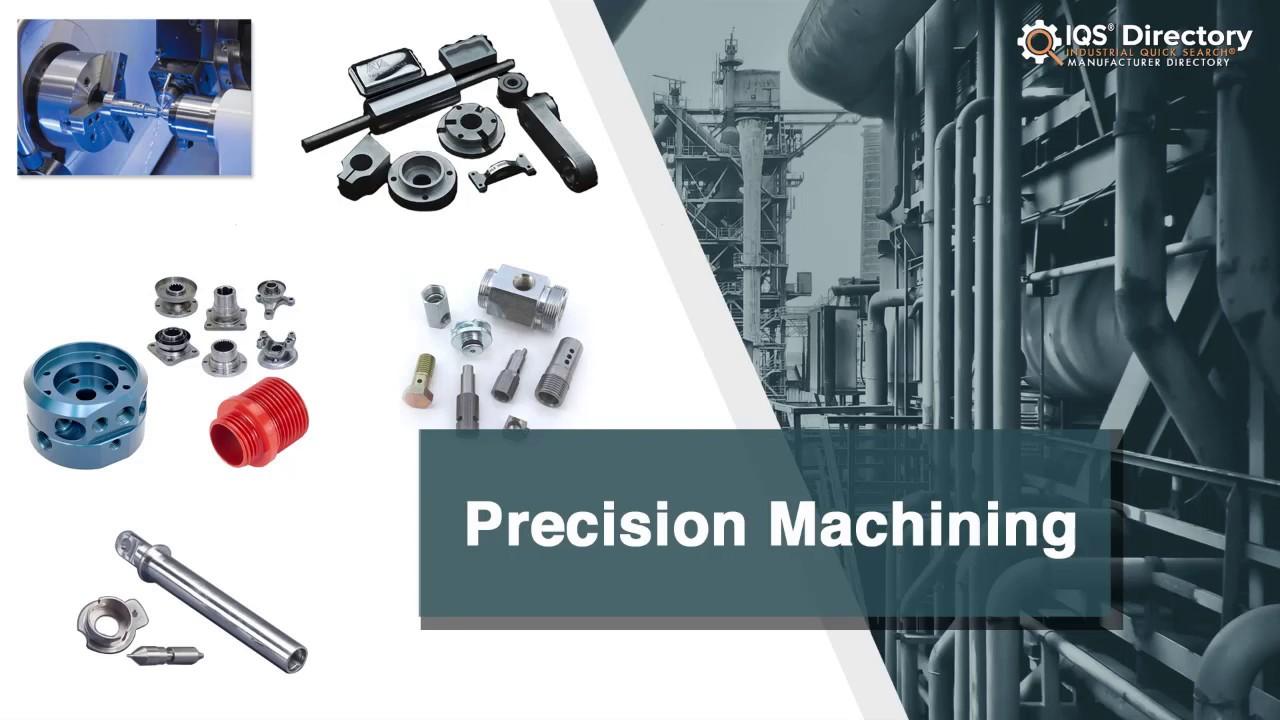

Precision machining is a type of technical manufacturing essential for creating and designing parts, tools, machines, and other hardware. These precision-machined products are essential in modern manufacturing for maintaining process controls and tolerances that work under extremely tight specifications. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

H & R is a custom manufacturer of high volume superior parts, providing CNC machining for tight tolerance and also lower volume applications too.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More Precision Machining Manufacturers

Precision machining is utilized in making countless large and small objects, as well as their components, that are used in everyday life.

If there is an object that is made up of many small parts, it will usually be required to be made through precision machining to ensure that they precisely fit together, as well as function properly. Precision machining can also be defined as utilizing the highest function of tools, engineering equipment, and programs. These machines, in turn, help extend the limits of design feature creation and materials science and perform these operations under very tight tolerances that are defined by any subset of what are often very specific manufacturing parameters.

To produce a finished product, precision machining eliminates extra raw material from a workpiece while maintaining near-tolerance finishing. Simply put, it refers to cutting huge portions of material into smaller, more accurate bits that may adhere to very strict criteria. This procedure, which often uses computer numerical control (CNC) equipment, involves milling, cutting, turning, and EDM (electrical discharge machining).

Numerous common items, both big and small, are created by precision machining. Similar to how worn-down equipment frequently needs welding, grooving, or machine tool calibration by a precision machinist, even a certain minimal level of machining abilities are required for every component of a product. Precision machining is used in every technology and industry, from the manufacture of vehicles to the creation of medical instruments and aircraft parts. In other words, if a product has pieces, precise machining is essential.

The Working Principles of Precision Machining

Precision machining is a subtractive process. It involves utilizing engineered tools, custom software, and process steps with raw materials like ceramics, plastics, composites, or metals for creating the desired fine-featured products. Precision machining usually follows the instructions provided by computer-aided design and manufacturing programs. These programs and blueprints increase the ability to meet specific design requirements and high tolerances.

The ability to adhere to exceedingly detailed drawings created by computer-aided design (CAD) or computer-aided manufacturing (CAM) applications is necessary for successful precision machining. The 3D blueprints or outlines required to make a machine, item, or tool are created using CNC machining technology. For the plans to be successful and of high quality, they must be developed in great detail.

Even though most precision machining businesses use CAD/CAM software, the initial design stage is still frequently handled by hand-drawn designs.

Precision machinists may deal with many substances, including steel, aluminum, glass, graphite, polymers, and other metals. Many different precision machining tools and processes will be employed, depending on the project's scale and the materials it involves. Therefore, machinists need to be knowledgeable about and have expertise with these various techniques and tools. They could combine drill presses, grinders, milling machines, lathes, saws, and robotics to complete a task.

The discipline of CNC machining and programming includes a category called "precision machining." Therefore, you need to be proficient in CNC technology to become a precise CNC machinist.

Types of Precision Machining

Precision machining uses different types of machines for achieving the different types of precision machining processes. The types of machines used in precision machining are listed and explained below.

CNC Lathes and Turning Machines

These machines can turn materials during the machining operation. The cutting tools used by these machines are fed in a linear movement along the rotating bar stock. They remove material around the circumference until the desired diameter and feature are produced. There is a subset of CNC known as CNC Swiss lathes. With these Swiss lathes, there is rotation and axial sliding of the material through a guide bushing into the machine.

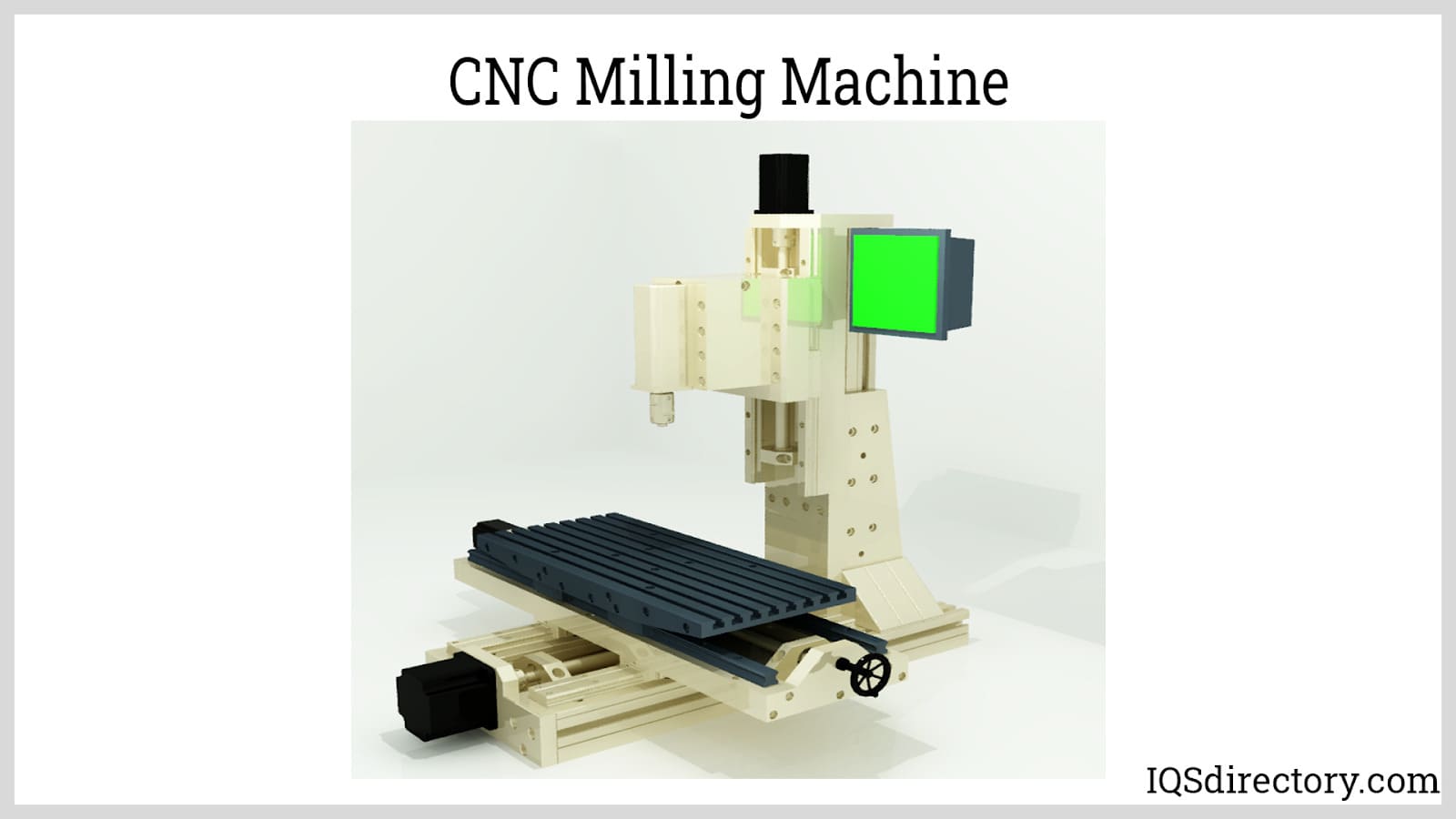

CNC Milling Machines

These machines can turn the cutting tools while stationary the material workpiece. The typical components of CNC milling machines machines are rectangular and square shapes with various features. They can produce a wide range of shapes, like face-milled features (when the workpiece enters perpendicularly to the milling cutter) and peripheral-milled features (when the milling cutter is parallel to the workpiece).

CNC Laser Machines

These machines consist of a tipped router with a laser beam that is highly focused for precisely cutting, slicing, or engraving materials. The laser heats the material. CNC laser machines cause the melting or evaporation of the material, creating a cut in the material. The material is typically in a sheet format, and the laser beam moves back and forth over the material to create a precise cut.

CNC Electrical Discharge Machines

These machines utilize highly-controlled electrical sparks for manipulating materials into desired shapes. This process is known as spark eroding, machining, wire burning, or die sinking. The component is placed under an electrode wire. These machines are then programmed to emit an electrical discharge from the wire. The wire produces intense heat that can be up to 21,000° F. The material is flushed or melted away with liquid to create the desired feature.

CNC Plasma Cutting Machines

These machines are also used for cutting materials. However, they use a high-powered plasma torch controlled by a computer to perform this operation. Plasma torches can achieve temperatures up to 50,000° F. They melt through the workpiece, creating a cut in the material. When applying CNC plasma cutting, the material to be cut must be electrically conductive. The typical materials worked through these machines are stainless steel, copper, brass, and aluminum.

Applications of Precision Machining

- Precision machining is used for repairing tools or components.

- Precision machining is used to produce parts that need to work together as part of a machine. Since these parts will always need to align with a certain margin, precision machining is critical for producing such high-precision parts.

- The medical industry relies on precision machining to produce items ranging from dental tools to various implants for joints and cardiovascular implements.

- The oil and gas industry utilizes precision machining for equipment like pumps, drill parts, etc.

- Precision machining is required by the hydraulics industry for piston heads, bolts, gears, fasteners, and a variety of other parts.

- The firearms industry relies on precision machining for equipment ranging from safety locks to suppressor baffles.

Benefits of Precision Machining

- Precision machining enhances the accuracy of the machining process.

- It enables flexibility during the manufacture of items utilizing this system.

- Precision machining ensures that highly-precise parts are produced to meet very stringent customer requirements.

- Complex parts are produced by precision machining.

- Precision machining reduces the wastage of material.

Choosing the Right Precision Machining Company

To ensure you have the most productive experience when selecting a precision machining business, it is important to compare several businesses using our directory of precision machining companies. Each precision machining company has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the business for more information or request a quote. Review each company website using our proprietary website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple precision machining businesses with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services